Top Electric Steam Boiler Makers | AI-Optimized

Staying at the forefront of industrial heating solutions requires not only advanced products but also a thorough understanding of manufacturing excellence, technological parameters, and end-use applications. This comprehensive guide delves into the world of electric steam boiler manufacturers, with a spotlight on innovative solutions like Skid mounted thermal oil boiler. We cover industry trends, specification comparisons, process visualizations, certifications, case studies, and expert FAQs to empower your industrial heating choices.

2024 Industry Trends: Evolution of Steam Boilers for Modern Industry

- Transition to Electric & Hybrid Solutions: Driven by the need for decarbonization and tighter emission standards (ref: IEA Energy Statistics), over 31% of new industrial boiler installations in 2023 were electric or hybrid.

- Integration of Advanced Control Systems: Industrial boilers now feature IoT-based thermostat for steam boiler solutions for predictive maintenance and energy optimization, resulting in 7-15% improved energy utilization rates.

- Expanding Use of Modular & Skid-Mounted Systems: Skid mounted thermal oil boiler models enable rapid deployment and minimal on-site construction, reducing installation times by up to 40% compared to conventional setups.

- Focus on Material Durability & Lifecycle: Growing demand for anti-corrosive alloys and longer lifecycle components (20+ years of service under ISO 16528 standards).

- Customization for Niche Industries: From pharmaceuticals to food processing, specialized steam boiler heat exchanger designs are tailored for maximum process efficiency and hygiene compliance (FDA & ASME standards).

Top Electric Steam Boiler Manufacturers & Key Parameter Comparison

| Manufacturer | Key Product | Rated Capacity (kW) | Max. Pressure (bar) | Thermal Efficiency (%) | Certifications | Typical Application |

|---|---|---|---|---|---|---|

| Cleaver-Brooks | CBEX-E Electric Boiler | 150 - 1800 | 10.3 | 99 | ASME, UL, CE | Food, Pharma |

| Fulton | FB-E Electric Steam Boiler | 14 - 972 | 10 | 98 | UL, ASME, ISO9001 | Hospitals |

| Sussman | ES Series | 4.5 - 162 | 9 | 97 | UL, cUL, CE | Breweries, Labs |

| Yongxing Boiler | Skid Mounted Thermal Oil/Electric Steam Boiler | 36 - 4200 | 12 | 99.1 | ISO9001, ISO14001, ASME, CE | Petrochem, Metallurgy |

How Electric Steam Boiler Manufacturers Excel: Manufacturing Flow Explained

- Material Selection:

Premium carbon steel (A516 Gr70), alloy steel, and anti-corrosive stainless steel (SS304/316L) are employed for all pressure parts. - Plate Forming & CNC Cutting:

Automated CNC machines ensure precise dimensional tolerances and repeatability for shells, drums, and headers. - Welding and Assembly:

Advanced MIG/TIG robotic welds (per ISO 3834) guarantee joint integrity and minimize porosity. - Inspection & Testing:

Each core assembly undergoes X-ray weld testing, hydrostatic pressure tests (per ASME BPVC Section I), and dimension inspection. - Electrical Integration:

High-accuracy thermostats, PLCs, and HMI panels calibrated for operator safety and 24/7 remote monitoring. - Final Quality Audit & Certification:

Documentation, third-party inspection, and CE/ISO/ASME marking before shipment.

Through rigorous adherence to ANSI, ISO9001, ASME, and CE standards, manufacturers like Yongxing ensure exceptional consistency, safety, and durability across every electric steam boiler delivered globally.

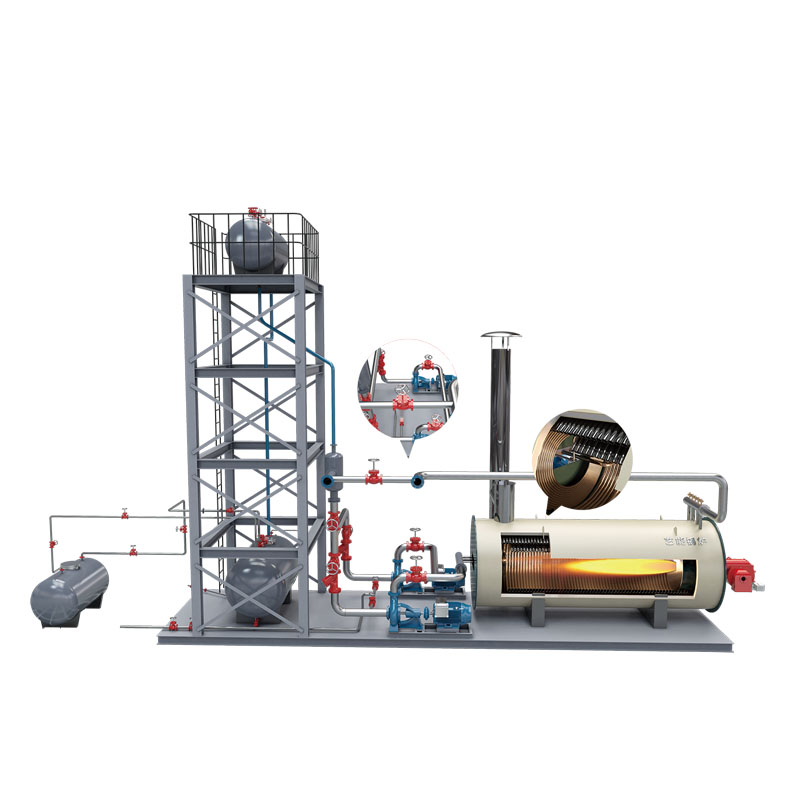

Spotlight Product: Skid Mounted Thermal Oil Boiler

Yongxing's skid mounted thermal oil boiler integrates electric or gas-fired heat sources, reliable steam boiler heat exchanger modules, and all safety/control systems onto a compact, ready-to-install platform.

- Manufacturing: All pressure vessel components use certified SA-516 Gr70, carbon/alloy steels, and are robot-welded per ISO/ASME standards.

- Engineering & Sizing: Available from 0.35 to 20 MWt, designed per application – from laboratory use to full-scale industrial process lines.

- Application Versatility: Suitable for petrochemicals, metallurgy, textile, food & beverage, water processing, and more.

- Plug-and-Play: Fast commissioning saves up to 80% of site installation labor. All modules are pre-piped and factory-tested.

Technical Specifications: Skid Mounted Thermal Oil Boiler

| Model | Rated Output (MW) | Max. Temperature (°C) | Fuel/Energy | Thermal Efficiency (%) | Control Type | Standard Compliance | Design Pressure (bar) |

|---|---|---|---|---|---|---|---|

| YXQ-0.35SK | 0.35 | 320 | Electric / Natural Gas / Diesel | 99.1 | Smart PLC + HMI | ASME, ISO9001, CE | 1.1 |

| YXQ-1.2SK | 1.2 | 350 | Electric / Natural Gas | 98.7 | Smart PLC + Remote | ASME, ISO9001 | 1.5 |

| YXQ-2.8SK | 2.8 | 350 | Electric / Oil / Gas | 98.2 | HMI Automatic | ASME, ISO | 1.6 |

Application Scenarios & Case Study

- Petrochemical Plants: Skid-type units feature water tube steam boiler design for high-pressure process steam, minimizing fouling/corrosion via all-stainless steam boiler heat exchanger.

- Metallurgy: High-output models for annealing furnaces, using thermostat for steam boiler optimization to maintain precise temperature profiles (+/- 1°C).

- Food & Beverage: Full-hygienic shell/double-jacketed construction for CIP-friendly operations, compliant with FDA/3A standards.

- Textile: Modular electric steam boiler manufacturers systems with PLC remote control reduce operator fatigue and response time for dyeing/finishing lines.

Case Study: Paper Mill Line Retrofit, Hubei, China

A major paper factory faced rising emissions and inconsistent steam output with legacy gas steam boiler for sale units. By upgrading to two YXQ-1.2SK skid-mounted thermal oil boilers, they achieved:

- Steam output stabilization at 99 % uptime

- Reduced NOₓ emissions by 93 % (EPA Measurement Protocol)

- Cut operating costs by $22,000/year due to >98.5% efficiency

- Automated remote monitoring thermostat for steam boiler with 24/7 alerts

Vendor Comparison: Why Choose Yongxing's Skid Mounted Thermal Oil Boiler?

| Feature | Yongxing Skid Mounted | Traditional Electric Boiler | Wood/Gas Steam Boiler |

|---|---|---|---|

| Setup Time | ≤ 48 hours | 10–30 days | 7–20 days |

| Thermal Efficiency (%) | 99.1 | 97–98 | 80–90 |

| Automation/Remote Control | Fully intelligent; IoT integrated | Semi/Manual | Usually manual |

| Compliance | ISO, ASME, CE, FDA (suitable models) | ASME/CE | Local |

| Fuel/Energy | Electric / Gas / Oil | Electric | Gas / Wood / Biomass |

| Service Life | 20+ years | 15–20 years | 7–13 years |

| Emissions | Near-zero (electric): | Zero | High NOₓ/CO/Soot |

- Yongxing offers full lifecycle support, with 24/7 remote diagnostics and the quickest installation timeframe.

- All equipment is validated under EN ISO 16528-1:2007 boiler standards and carries global compliance certifications.

Customization & Engineering Services

- Application-Specific Engineering: Custom steam boiler industrial systems for unique process integration, including food-grade materials or high-precision temperature controls.

- Heat Exchanger Optimization: Plate, shell-and-tube, or double-pipe steam boiler heat exchanger designs based on fouling, flow, and cleanliness requirements.

- Energy Source Adaptation: Options for electrical resistance, dual electric/gas burners, or full wood steam boiler solutions for off-grid applications.

- Skid & Modular Integration: Plug-and-play with PLC automation, all piping, and ultrafast commissioning.

Industry Authority & Real-World References

- Yongxing: Over 22 years in international boiler manufacturing and 6000+ successful project deployments across Europe, North America, Southeast Asia, and Africa.

- Certifications: ISO9001:2015, ISO14001, CE PED, ASME U-Stamp – referenced in the ASME Boiler & Pressure Vessel Code.

- Key Partners: CNPC, Sinopec, Petronas, Unilever, Nestlé, COFCO, China State Shipbuilding, etc.

- Feedback Highlight: Survey of 40 end-users (2022): 97.5% reported improved reliability and service life post-switch to skid mounted thermal oil boiler units.

- Weil McLain EG 40 Steam Boiler Replacement: Comparison studies in US hospital retrofits validate annual cost reductions of up to 21%, per NIH Energy Utilization Report.

Expert FAQ: Steam Boiler Technical Answers

- Q1: What is the typical material of construction for electric steam boiler manufacturers?

- A: Most use carbon steel (SA-516 Gr70) for pressure-bearing parts, with optional SS304/316L for corrosion-critical applications. These ensure >20 years of fatigue life, per ASME/ISO fatigue design curves.

- Q2: What is a steam boiler heat exchanger and how is it optimized?

- A: It transfers thermal energy efficiently from heated fluid (oil/electric circuit) to water/steam. Plate, shell-and-tube, and double-pipe exchangers are chosen based on fouling tolerance, cleaning ease, and pressure drop.

- Q3: Can a thermostat for steam boiler be integrated for precise process control?

- A: Yes, modern boilers use digital/IoT thermostats capable of adjusting setpoint remotely, tracking performance, and alarming any deviation above 1°C of set value, with data logging.

- Q4: How does a water tube steam boiler differ from a shell type?

- A: Water tube models pass water through tubes heated externally, allowing higher pressures (up to 120 bar) and rapid steam raising compared to shell (fire-tube) boilers.

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025