Industrial Thermal Oil Boilers | Efficient & Reliable Heating

The Evolution and Efficiency of Industrial Thermal Oil Boiler Systems

In the demanding landscape of industrial process heating, the choice of a heat transfer medium and system is paramount for efficiency, safety, and operational longevity. Among the various solutions, the thermal oil boiler stands out as a superior alternative to traditional steam boilers, especially for applications requiring high temperatures at low pressures. These systems, often referred to as hot oil heaters or thermal fluid heaters, utilize specialized thermal fluids to transfer heat from a combustion source to a process, facilitating precise temperature control and uniform heat distribution. The inherent advantages of a closed-loop thermal oil system, such as the absence of scale formation, blowdown losses, and corrosion issues common in water-based systems, contribute significantly to reduced operational costs and extended equipment life. Current industry trends are heavily leaning towards solutions that offer enhanced energy efficiency, lower emissions, and greater operational flexibility, pushing manufacturers to innovate with advanced designs and control mechanisms. This includes the development of compact, modular units like the Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater, designed to meet diverse industrial demands while adhering to stringent environmental regulations. The continuous evolution of thermal fluid technology and boiler design ensures that these systems remain at the forefront of industrial heating solutions.

The market for industrial heating equipment is experiencing significant growth, driven by expansion in manufacturing sectors, stricter environmental compliance requirements, and the global push for sustainable energy solutions. Within this context, the demand for sophisticated thermal oil boiler units is escalating, particularly for systems that can efficiently handle a wide range of fuel types, from natural gas and diesel oil to biomass and waste heat. Businesses are increasingly prioritizing solutions that not only deliver high thermal efficiency but also integrate seamlessly with existing plant infrastructure and offer advanced automation for optimized performance. The shift towards digitalization, including features like remote monitoring and predictive maintenance, is transforming the operational paradigm of industrial heating. This focus on integrated, intelligent heating solutions underscores the critical role of the thermal oil boiler in modern industrial processes, providing a reliable, safe, and cost-effective method for achieving high-temperature heating requirements across a multitude of applications. Furthermore, the capacity for manufacturers to provide bespoke solutions, including oem boiler thermal oil units, caters directly to the unique specifications and operational challenges faced by various industries, reinforcing the versatility and adaptability of thermal fluid heating technology.

Precision Engineering: The Manufacturing Journey of a Thermal Oil Boiler

The production of a high-performance thermal oil boiler is a testament to precision engineering, involving a meticulously controlled manufacturing process that ensures durability, safety, and optimal thermal efficiency. It begins with the selection of premium-grade materials, typically high-strength alloy steels and specialized stainless steels, chosen for their excellent thermal stability, corrosion resistance, and ability to withstand high temperatures and pressures. Key components, such as the coil and furnace tubes, undergo stringent material testing, including ultrasonic and radiographic inspections, to verify metallurgical integrity. The manufacturing sequence involves critical stages like automated cutting and bending of tubes to achieve the precise helical or serpentine coil configurations that maximize heat transfer surface area. Advanced welding techniques, often utilizing submerged arc welding (SAW) or gas tungsten arc welding (GTAW), are employed to ensure robust, leak-proof joints. Post-welding, non-destructive testing (NDT) methods like X-ray and ultrasonic flaw detection are rigorously applied to every weld seam, adhering strictly to international standards such as ASME Boiler and Pressure Vessel Code, ISO 9001, and ANSI codes, guaranteeing structural soundness and compliance.

Beyond fabrication, the manufacturing process for a boiler thermal oil unit incorporates sophisticated machining and assembly. CNC (Computer Numerical Control) machining ensures unparalleled accuracy in drilling, shaping, and finishing various parts, contributing to precise fit and reduced assembly time. Components such as the combustion chamber, insulation layers, and external casings are then meticulously assembled. High-density refractory insulation materials are strategically installed to minimize heat loss and enhance overall thermal efficiency, an imperative for energy conservation. A critical phase involves hydrostatic testing, where the completed pressure parts are subjected to pressures significantly higher than their maximum operating pressure to detect any potential leaks or structural weaknesses. This rigorous testing, combined with comprehensive functional tests of control systems, safety interlocks, and auxiliary equipment, ensures that each Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater unit meets the highest performance and safety benchmarks. The typical lifespan of a well-maintained thermal oil system exceeds 20-30 years, showcasing the robust engineering and manufacturing quality. These boilers are indispensable in industries such as petrochemicals, textiles, food processing, asphalt production, and timber processing, where their ability to deliver stable, high-temperature heat efficiently without the corrosive effects of steam is invaluable. Their closed-loop design, for example, prevents oxygen ingress and subsequent corrosion, significantly reducing maintenance needs and improving operational uptime compared to open steam systems.

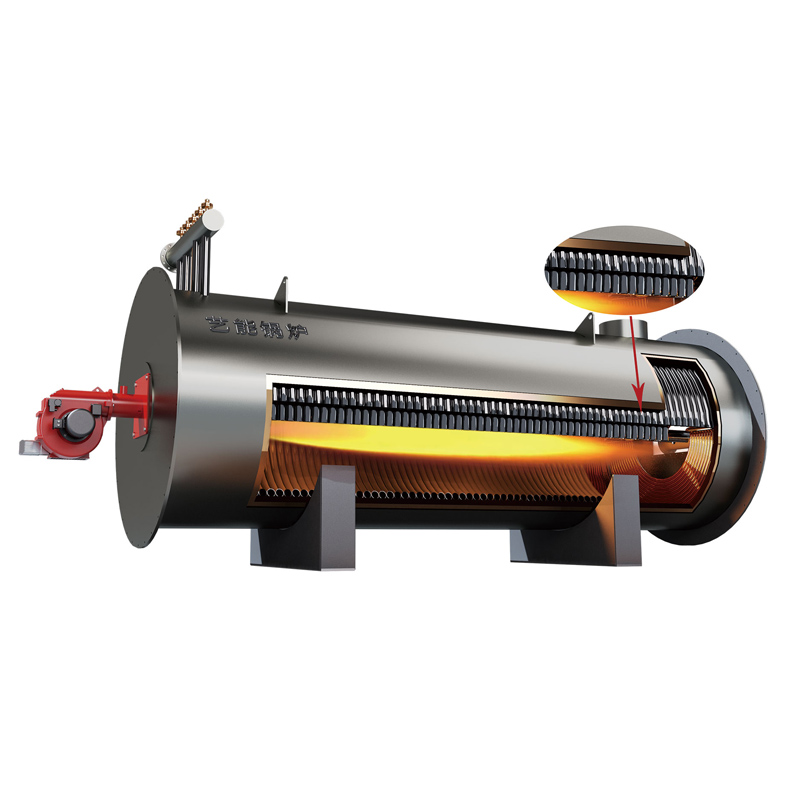

Figure 1: Internal structure of a meticulously crafted thermal oil boiler, highlighting precision components.

Technical Superiority: Parameters and Performance of Thermal Oil Boilers

The technical specifications of a thermal oil boiler are critical determinants of its suitability for specific industrial applications. Key parameters include thermal output (measured in kcal/hr or BTU/hr), maximum operating temperature, design pressure, and thermal efficiency. Unlike steam boilers that operate at extremely high pressures to achieve high temperatures, thermal oil systems can reach temperatures exceeding 300°C (572°F) at virtually atmospheric pressure, significantly reducing safety risks and structural requirements. The thermal fluid, often a synthetic or mineral oil, maintains its liquid phase throughout the heating and cooling cycle, preventing phase change issues like condensation and flashing. High thermal efficiency, typically ranging from 85% to over 92% for well-designed units, is achieved through optimized heat exchange surfaces, effective insulation, and efficient combustion management. Advanced combustion technologies, such as low NOx burners, are integrated to ensure compliance with stringent emission standards, an increasingly vital aspect for industrial operations worldwide.

The performance advantages of a thermal oil boiler extend beyond mere thermal output. Their ability to deliver consistent, uniform heat at precise temperatures is crucial for sensitive processes in industries like chemical processing and pharmaceuticals. The inherent resistance of thermal oil to scale formation and corrosion eliminates the need for water treatment, blowdown, and constant monitoring, drastically reducing maintenance overheads and operational downtime. For example, in textile dyeing, a boiler thermal oil ensures even heat distribution, critical for consistent color absorption and fabric quality, avoiding hotspots that can damage materials. Furthermore, the longevity of thermal fluid, often lasting several years before requiring replacement, contributes to lower lifecycle costs. The enclosed nature of the thermal oil system also means minimal fluid loss, further enhancing its economic and environmental appeal. Below is a table outlining typical parameters for a high-performance industrial thermal oil boiler, such as the Horizontal/Vertical type YQW/L series, providing a clear overview of their capabilities.

| Parameter | Typical Range/Value | Description/Advantage |

|---|---|---|

| Thermal Output | 300,000 to 12,000,000 kcal/hr | Capacity to meet diverse industrial heating demands, from small processes to large-scale operations. |

| Max. Operating Temperature | Up to 350°C (662°F) | Enables high-temperature processes without high pressure, enhancing safety and design simplicity. |

| Design Pressure | Atmospheric to 0.8 MPa (116 psi) | Significantly lower than steam boilers, reducing safety risks and regulatory burdens. |

| Thermal Efficiency | 88% - 92% (for gas/oil fired) | Optimized heat transfer and insulation for minimal energy loss, contributing to lower operating costs. |

| Fuel Types | Natural Gas, Diesel Oil, Heavy Oil, Biogas, LPG | Flexibility in fuel choice allows for adaptation to energy availability and cost fluctuations. |

| Coil Material | Seamless Steel Tube (e.g., GB/T8163, ASTM A106 Gr.B) | Ensures high-temperature strength and corrosion resistance for long-term reliability. |

| Control System | PLC-based with Touch Screen HMI | Provides precise temperature control, automated operation, and comprehensive safety interlocks. |

Diverse Applications and Strategic Impact Across Industries

The versatility of the thermal oil boiler makes it an indispensable heating solution across a broad spectrum of industrial applications, particularly where precise temperature control and high operational temperatures are crucial. In the petrochemical industry, for instance, boiler thermal oil systems are vital for heating reaction vessels, reboilers, and distillation columns, maintaining stable temperatures for critical chemical synthesis and separation processes. Their ability to operate at low pressures while achieving temperatures up to 350°C dramatically enhances safety in environments dealing with flammable or hazardous substances. Similarly, in the asphalt and bitumen industry, thermal oil heaters are used for heating storage tanks and mixing plants, ensuring consistent viscosity for paving and roofing applications, even in cold climates. The textile industry relies on thermal oil for dyeing and drying processes, where uniform heat transfer prevents damage to delicate fabrics and ensures consistent color quality.

Beyond these, the food and beverage industry utilizes thermal oil system for cooking, frying, and sterilization, where the clean, dry heat prevents product contamination and allows for precise temperature profiles essential for food quality and safety. The timber and woodworking sectors benefit from thermal oil for wood drying kilns and panel pressing, facilitating efficient moisture removal and bonding processes. Even in metallurgy, for specific annealing or tempering furnaces, thermal oil can provide the controlled high temperatures required. The adaptability extends to specialized applications, highlighting the importance of customized solutions. When standard configurations are insufficient, oem boiler thermal oil manufacturing becomes critical, allowing for boilers to be designed and fabricated to precise client specifications regarding fuel type, space constraints, capacity requirements, and integration with existing control systems. This tailored approach ensures optimal performance and seamless integration, delivering maximum value. The inherent advantages, such as low maintenance and high operational stability, contribute significantly to increased productivity and reduced downtime across all these diverse sectors.

Figure 2: A thermal oil boiler integrated into an industrial facility, demonstrating its operational footprint.

Customization and Competitive Edge: Tailored Thermal Solutions

In the competitive landscape of industrial heating, the ability to offer highly customized solutions is a significant differentiator. While standard Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater units serve a wide array of general applications, specific industrial requirements often necessitate bespoke designs. This is where expertise in oem boiler thermal oil manufacturing becomes paramount. Customization can involve tailoring the boiler’s dimensions to fit confined spaces, optimizing burner systems for specific fuel characteristics (e.g., waste oil or specialized gases), integrating advanced PLC-based control systems for complex process automation, or designing specialized heat recovery modules to maximize overall plant efficiency. For instance, a pharmaceutical company might require ultra-precise temperature control with minimal fluctuations, necessitating a control system with higher fidelity sensors and faster response times, or specific material certifications for pharmaceutical-grade cleanroom environments. Such tailored solutions ensure that the thermal oil boiler operates at peak efficiency within the client’s unique operational parameters, minimizing energy waste and optimizing output.

When considering a thermal oil boiler, a comparative analysis of different configurations helps in making an informed decision. For example, selecting between a horizontal and vertical type depends largely on available footprint and access requirements. Horizontal designs often offer easier access for maintenance and cleaning of specific components, while vertical designs conserve valuable floor space, making them ideal for compact facilities. Fuel type flexibility is another key comparison point, with gas-fired units offering cleaner combustion and potentially lower operating costs in regions with stable natural gas supply, while diesel or heavy oil fired units provide greater energy independence and are suitable for remote locations. Our Horizontal/Vertical type YQW/L series offers both configurations and multi-fuel options to cater to these diverse needs. Key competitive advantages include robust construction for extended lifespan, advanced safety interlocks conforming to international standards (e.g., ISO 17025 for testing), high thermal efficiencies validated through rigorous testing, and a comprehensive after-sales support system. This commitment to quality and service ensures that our boiler thermal oil units deliver reliable and superior performance throughout their operational life.

| Feature | Horizontal Type (YQW) | Vertical Type (YQL) |

|---|---|---|

| Footprint | Wider, longer footprint | Smaller, more compact footprint |

| Height Requirement | Lower height clearance needed | Higher vertical clearance required |

| Maintenance Access | Generally easier access to internal components for inspection and maintenance. | Access can be more restricted; may require specialized lifting equipment for some components. |

| Installation | Simpler installation for larger capacities. | Ideal for space-constrained facilities, requiring less floor area. |

| Typical Applications | Larger industrial plants with ample floor space. | Facilities with limited ground area, often used for smaller to medium capacities. |

| Draft System | Usually forced draft. | Often natural or induced draft depending on design. |

Building Trust: Quality Assurance, Support, and Real-World Success

Establishing and maintaining trust is fundamental in B2B relationships, especially for critical infrastructure like a thermal oil boiler. Our commitment to trustworthiness is evidenced by adherence to rigorous quality control standards and transparent operational practices. Every unit, whether a standard Horizontal/Vertical type YQW/L or a specialized oem boiler thermal oil, undergoes a multi-stage quality assurance process. This includes material traceability, in-process inspections at every manufacturing stage, and final performance testing in accordance with international norms such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and OHSAS 18001 for occupational health and safety. Our products are designed and manufactured to meet ASME standards for pressure vessels and comply with local regulatory requirements like PED for the European Union or national boiler codes. Decades of experience in the industry, coupled with strategic partnerships with reputable component suppliers, underpin our authoritative position in the market. Our extensive service network, with highly trained technicians, ensures prompt and efficient support, from installation and commissioning to routine maintenance and emergency repairs, safeguarding operational continuity for our clients.

Understanding the critical nature of industrial heating, we provide comprehensive support designed to enhance the experience and reliability of every boiler thermal oil system. Our standard product warranty covers defects in materials and workmanship for a significant period, typically 12 to 24 months after commissioning or 18 to 30 months after delivery, whichever comes first, underscoring our confidence in product durability. We also offer extended warranty options and tailored service contracts to meet specific client needs for long-term operational assurance. Delivery cycles are carefully managed, with typical lead times ranging from 8 to 16 weeks depending on customization and capacity requirements, clearly communicated and diligently adhered to. This transparency in delivery and support, combined with comprehensive technical documentation and operator training programs, empowers clients to maximize the uptime and efficiency of their thermal oil system. A recent success story involved a large-scale chemical plant that replaced an aging steam system with our YQW-series thermal oil boiler, resulting in a documented 15% reduction in annual energy consumption and a 30% decrease in maintenance costs within the first year, demonstrating tangible returns on investment and strengthening client confidence.

Figure 3: Advanced PLC control panel for precise and safe thermal oil boiler operation.

Frequently Asked Questions (FAQ) about Thermal Oil Boilers

Q1: What is the primary advantage of a thermal oil boiler over a steam boiler?

The primary advantage of a thermal oil boiler lies in its ability to achieve very high temperatures (up to 350°C) at extremely low or even atmospheric pressures. This contrasts sharply with steam boilers, which require significantly high pressures to reach comparable temperatures, leading to higher safety risks, more stringent regulatory requirements, and greater structural demands. Thermal oil systems also eliminate issues like scale formation, corrosion, and blowdown losses, which are common with water-based systems, thus reducing maintenance costs and extending the system's operational lifespan. The closed-loop nature of a thermal oil system also prevents fluid loss and the need for constant make-up water, further contributing to efficiency and cost savings. This makes them ideal for processes requiring precise, stable high-temperature heat without the complexities and risks associated with high-pressure steam.

Q2: How is the thermal fluid maintained in a boiler thermal oil system?

Maintaining the thermal fluid in a boiler thermal oil system involves several key practices to ensure its longevity and system efficiency. Regular fluid analysis is crucial to monitor its condition, checking for degradation indicators such as acidity, viscosity changes, and the presence of carbon residues. This allows for timely top-ups or fluid replacement, preventing damage to the system components. Ensuring the thermal oil system remains a closed loop and is properly degassed during initial setup prevents oxygen ingress, which can accelerate fluid degradation. Proper system design, including expansion tanks that accommodate thermal expansion and de-aeration tanks, also plays a critical role. Filtration systems are often integrated to remove particulates, while robust temperature control prevents overheating, which is a primary cause of thermal fluid breakdown. Adherence to manufacturer guidelines for fluid handling and system operation is paramount for optimal performance and extended fluid life.

Q3: Can a thermal oil boiler be customized for specific industrial applications?

Absolutely. Customization is a significant strength of modern thermal oil boiler manufacturers, particularly those offering oem boiler thermal oil solutions. We understand that each industry and even individual facility may have unique requirements concerning space constraints, specific fuel types (e.g., waste gases, specific biomass), precise temperature profiles, or integration with existing plant automation systems. Customization can involve modifying the boiler's physical dimensions (horizontal vs. vertical configuration), incorporating specialized burners for alternative fuels, designing bespoke control logic for complex processes, or selecting specific materials for extreme operating conditions or corrosive environments. Our engineering team collaborates closely with clients to understand their exact needs, leveraging advanced CAD/CAM and simulation tools to design a thermal oil heater that not only fits perfectly into their operational environment but also maximizes efficiency, safety, and return on investment.

Conclusion

The thermal oil boiler represents a cornerstone of efficient, safe, and reliable industrial heating, offering distinct advantages over traditional steam systems, particularly for high-temperature applications. Its closed-loop design, low-pressure operation, and superior heat transfer capabilities translate into significant operational savings, reduced maintenance, and enhanced safety. As industries continue to evolve towards more sustainable and efficient processes, the demand for advanced thermal oil system solutions, capable of handling diverse fuel sources and integrating with smart control technologies, will only grow. Through meticulous manufacturing processes, adherence to international standards, and a steadfast commitment to customer-centric customization and support, manufacturers are continually pushing the boundaries of what these systems can achieve. Investing in a high-quality boiler thermal oil is not just a purchase of equipment; it's an investment in the long-term efficiency, productivity, and safety of your industrial operations.

References:

- American Society of Mechanical Engineers (ASME). Boiler and Pressure Vessel Code.

- International Organization for Standardization (ISO). ISO 9001: Quality Management Systems – Requirements.

- American National Standards Institute (ANSI). Various standards related to industrial boilers and pressure vessels.

- European Pressure Equipment Directive (PED) 2014/68/EU.

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025

-

Electric Steam Boiler Manufacturers | Industrial Power & EfficiencyNewsAug.12,2025