Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial Solutions

Introduction to Electric Steam Boiler Manufacturing

In the rapidly evolving industrial landscape, the demand for efficient, clean, and reliable steam generation solutions is paramount. Among the various options, electric steam boilers stand out for their environmental benefits and operational precision. The market for these critical industrial components is driven by stringent environmental regulations, a push for energy efficiency, and the increasing adoption of electrification across diverse sectors. Understanding the intricacies of leading electric steam boiler manufacturers is crucial for industrial decision-makers seeking optimal thermal energy systems. This guide delves into the manufacturing processes, technical specifications, application scenarios, and key advantages that define excellence in this specialized field.

Unlike traditional fossil fuel-fired boilers, such as a gas steam boiler for sale or a wood steam boiler, electric variants offer distinct advantages in terms of footprint, emissions, and responsiveness. They are increasingly chosen for applications requiring precise temperature control and minimal environmental impact, integrating seamlessly with modern industrial processes that demand high levels of automation and compliance.

Industry Trends and Market Dynamics

The global market for industrial boilers, including electric steam boilers, is projected to grow significantly, driven by factors such as industrialization, urbanization, and increasing investment in energy-efficient technologies. Key trends influencing electric steam boiler manufacturers include:

- Sustainability and Decarbonization: A strong push towards reducing carbon footprints is accelerating the adoption of electric boilers, especially where renewable electricity sources are available. This aligns with global climate goals and corporate sustainability initiatives.

- Automation and Smart Integration: Modern electric steam boilers often feature advanced control systems, including IoT capabilities, allowing for remote monitoring, predictive maintenance, and seamless integration with broader plant management systems. The precise control offered by an advanced thermostat for steam boiler systems is now a standard expectation.

- Energy Efficiency: Continuous innovation focuses on maximizing thermal efficiency and minimizing heat losses, leading to lower operating costs and enhanced competitiveness.

- Modular and Compact Designs: As industrial spaces become more constrained, there's a growing demand for compact, modular boiler systems that offer flexibility in installation and scalability.

- Robust Safety Standards: Adherence to international safety standards (e.g., ASME, PED) remains a critical driver, ensuring reliable and safe operation in demanding industrial environments.

The market is also seeing increased demand for specialized applications, requiring tailored solutions from electric steam boiler manufacturers that can handle specific pressure, temperature, and steam quality requirements.

Detailed Manufacturing Process of Electric Steam Boilers

The production of a high-quality electric steam boiler involves a rigorous, multi-stage process, meticulously adhering to international standards to ensure reliability, safety, and efficiency.

Phase 1: Design and Material Sourcing

- Conceptual Design & Engineering: Utilizing CAD/CAE software, engineers develop detailed blueprints, considering thermal dynamics, pressure vessel integrity, and electrical system integration. Design adheres to ASME Boiler and Pressure Vessel Code, EN 12953, or local regulatory requirements.

- Material Selection: High-grade steel alloys (e.g., SA-516 Grade 70 for pressure parts, stainless steel for specific components) are selected for their excellent mechanical properties, corrosion resistance, and ability to withstand high temperatures and pressures. Electrical heating elements are typically made from nickel-chromium alloys.

- Supplier Qualification: Raw materials are sourced only from certified suppliers, ensuring traceability and compliance with industry standards like ASTM or EN specifications.

Phase 2: Fabrication of Pressure Parts

- Plate Cutting & Forming: Steel plates are precisely cut using CNC plasma or laser cutters. Then, they are rolled or pressed into cylindrical shells, dished heads, or other complex geometries.

- Welding: This is a critical stage. Qualified welders, certified to standards such as AWS D1.1 or EN ISO 9606, perform welding using techniques like Submerged Arc Welding (SAW), Gas Tungsten Arc Welding (GTAW), or Shielded Metal Arc Welding (SMAW). All welds undergo Non-Destructive Testing (NDT) including radiographic inspection (X-ray/gamma-ray), ultrasonic testing, magnetic particle testing, and dye penetrant inspection, ensuring weld integrity and freedom from defects.

- Nozzle and Fitting Integration: Connections for steam outlet, feedwater inlet, blowdown, safety valves, and instrumentation are precisely cut and welded onto the pressure vessel.

Phase 3: Heating Element Integration and Assembly

- Heating Element Fabrication & Installation: High-density, high-purity electrical resistance elements are manufactured and then securely installed into the boiler shell. These elements are designed for long service life, typically exceeding 10-15 years under normal operating conditions.

- Internal Component Assembly: Components such as baffles, demisters, and feed-water distribution pipes are installed within the pressure vessel to optimize steam separation and water circulation, crucial for efficient steam generation in a steam boiler industrial application.

- Insulation & Cladding: High-temperature insulation (e.g., mineral wool, ceramic fiber) is applied to the boiler shell to minimize heat loss, covered by a protective sheet metal cladding (e.g., painted mild steel or stainless steel).

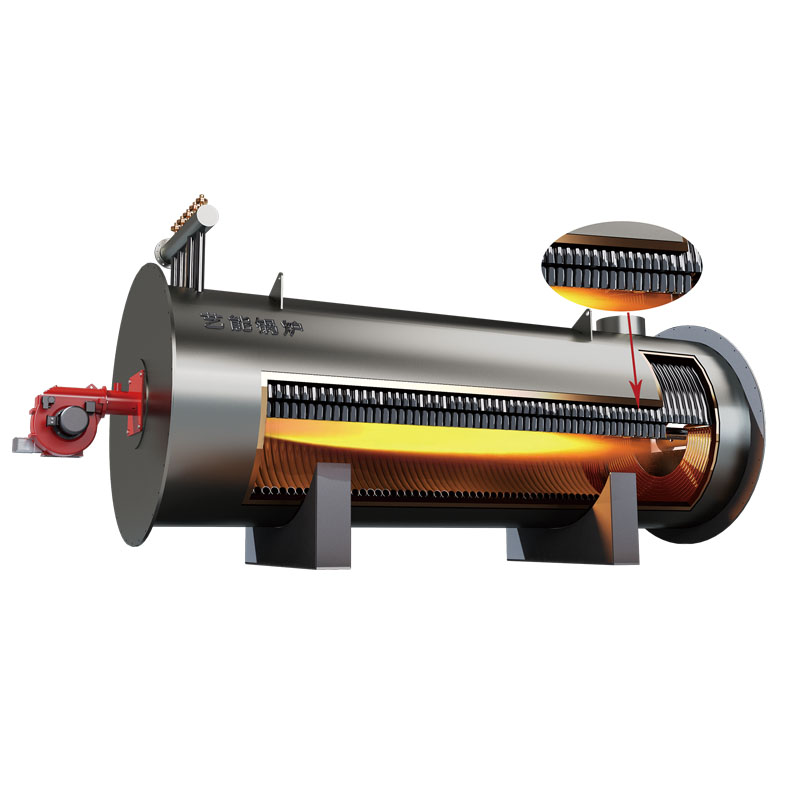

Image 1: Precision engineering at the core of electric steam boiler manufacturing.

Phase 4: Electrical, Control Systems & Final Testing

- Control Panel Integration: Electrical components, including contactors, relays, PLCs, safety interlocks, and a sophisticated thermostat for steam boiler, are wired into a dedicated control panel, ensuring precise operation and adherence to electrical safety standards (e.g., IEC 60204).

- Hydrostatic Testing: The completed pressure vessel undergoes hydrostatic testing, where it is filled with water and pressurized to 1.5 times the maximum allowable working pressure. This verifies the structural integrity and leak-tightness of all welds and connections.

- Functional & Performance Testing: The boiler is energized to verify the operation of heating elements, controls, safety devices (pressure switches, low-water cutoffs, safety valves), and overall steam generation performance. Efficiency, steam quality, and response times are measured.

- Quality Control & Certification: Each boiler undergoes a final inspection against a comprehensive checklist. Documentation, including material certificates, NDT reports, and pressure vessel certificates (e.g., CE, ASME U Stamp, ISO 9001), is compiled for shipment.

Target industries for these rigorously manufactured boilers include petrochemical, metallurgy, food & beverage, pharmaceuticals, textiles, water supply & drainage, and healthcare, where energy saving, corrosion resistance, and precise steam supply are critical advantages. The meticulous process ensures a service life often exceeding 20-30 years with proper maintenance.

Technical Specifications and Parameters

Electric steam boiler manufacturers offer a range of products designed to meet diverse industrial requirements. Key technical parameters include steam output, working pressure, efficiency, and electrical specifications.

Image 2: Advanced control systems ensure optimal performance and safety.

Typical Electric Steam Boiler Specifications

| Parameter | Range/Description |

|---|---|

| Steam Output Capacity | 50 kg/hr to 5,000 kg/hr (10 BHP to 1,000 BHP) |

| Working Pressure | 0.7 MPa to 1.6 MPa (100 PSI to 232 PSI), higher upon request |

| Design Pressure | Up to 1.8 MPa (260 PSI) |

| Electrical Power Input | 30 kW to 3,000 kW, available in various voltages (208V, 400V, 480V, 600V, 4160V) |

| Thermal Efficiency | > 99% (due to direct heating and minimal flue gas loss) |

| Steam Quality | Dry Saturated Steam |

| Control System | PLC-based with HMI, fully automatic operation, remote monitoring options |

| Safety Features | Multiple over-pressure protection, low water cutoff, high water alarm, fault self-diagnosis |

| Heating Elements | Incoloy or Stainless Steel (AISI 316L) |

| Expected Service Life | 20+ years with proper maintenance |

These specifications highlight the robustness and advanced engineering of modern electric steam boilers. The efficiency of nearly 100% is a critical advantage, as virtually all electrical energy is converted into heat for steam generation, minimizing energy waste compared to systems like a traditional steam boiler heat exchanger with associated flue gas losses.

Application Scenarios and Target Industries

The versatility and precise control offered by electric steam boilers make them suitable for a vast array of industrial and commercial applications.

- Food & Beverage: For sterilization, cooking, pasteurization, and cleaning-in-place (CIP) processes, where clean, contaminant-free steam is essential. The absence of combustion byproducts ensures product purity.

- Pharmaceuticals & Healthcare: Autoclaves, humidification, and laboratory sterilization require high-purity steam. Electric boilers provide consistent, reliable steam without emissions, crucial for sterile environments.

- Textile Industry: Steaming for dyeing, finishing, and pressing processes. Rapid steam generation and precise temperature control are key benefits.

- Chemical & Petrochemical: Process heating, reaction vessel jackets, and trace heating. The inherent safety of electric boilers reduces explosion risks compared to fossil fuel alternatives in hazardous environments.

- Commercial Laundries: For pressing and drying operations, offering quick heat-up and efficient steam production.

- Humidification & HVAC: Providing clean steam for air humidification in commercial buildings, data centers, and cleanrooms.

- District Heating: As supplementary or primary heat sources in urban heating networks, especially where electricity is cost-effective or surplus renewable energy is available.

Even niche applications, where a specific model like a weil mclain eg 40 steam boiler might typically be found, are increasingly seeing electric alternatives for their environmental and operational benefits. The suitability extends to small-scale process steam needs where a dedicated water tube steam boiler might be overkill, but consistent, high-quality steam is still required.

Technical Advantages of Electric Steam Boilers

The advantages of electric steam boilers are particularly compelling in modern industrial settings.

- High Efficiency: With almost 99% thermal efficiency, electric boilers convert nearly all electrical energy into steam, minimizing operational costs and maximizing energy utilization.

- Zero Emissions at Point of Use: As there is no combustion, electric boilers produce no NOx, SOx, CO2, or particulate matter emissions, contributing to cleaner air and easier compliance with environmental regulations.

- Precise Temperature and Pressure Control: Advanced electrical controls allow for very accurate modulation of steam output and pressure, essential for sensitive processes.

- Compact Footprint: Absence of fuel storage tanks, complex burner systems, and flue stacks results in a smaller physical footprint, ideal for space-constrained facilities.

- Quiet Operation: Without combustion noise or forced draft fans, electric boilers operate very quietly, improving working conditions.

- Rapid Startup and Response: Electric boilers can reach operating pressure quickly and respond rapidly to load changes, offering significant operational flexibility.

- Enhanced Safety: Reduced risks associated with fuel handling, combustion hazards, and flue gas exhaust systems. Multiple interlocking safety features are standard.

- Low Maintenance: Fewer moving parts and no combustion-related issues (soot, ash, burner cleaning) lead to lower maintenance requirements and reduced downtime.

Image 3: Robust construction ensures durability and long-term performance.

Vendor Comparison and Selection Criteria

Choosing the right electric steam boiler manufacturers requires careful consideration of several factors beyond just initial cost. A holistic approach focusing on total cost of ownership (TCO) and long-term partnership is advisable.

Key Comparison Points for Electric Steam Boiler Manufacturers

| Criteria | Reputable Manufacturer A (Example) | Reputable Manufacturer B (Example) |

|---|---|---|

| Certifications & Standards | ASME U Stamp, CE/PED, ISO 9001, UL Listed | ISO 9001, CE, CSA B51, National Board Certified |

| Efficiency (Operating) | >99% | >99.5% |

| Control System | PLC with HMI, Modbus/Ethernet IP, remote access | Proprietary digital controller, BACnet/Modbus integration |

| Customization Options | Pressure, voltage, materials, skid-mounted, specific auxiliaries | Capacity, pressure, advanced energy management features, custom footprint |

| After-Sales Support | Global service network, 24/7 technical support, parts availability | Regional service centers, online diagnostics, dedicated project managers |

| Warranty (Standard) | 1 year parts & labor, 5 years pressure vessel | 2 years parts, 10 years pressure vessel |

Beyond these technical comparisons, evaluate the manufacturer's reputation, years in business, client testimonials, and their commitment to research and development. A strong engineering team capable of providing bespoke solutions is a significant asset.

Customized Solutions from Electric Steam Boiler Manufacturers

Industrial operations rarely fit a "one-size-fits-all" mold. Leading electric steam boiler manufacturers understand this and excel in providing customized solutions tailored to specific client needs. This can involve:

- Specific Capacity & Pressure Requirements: Designing boilers to produce exact steam flow rates and pressures, optimizing energy use and process integration.

- Voltage & Power Options: Adapting to available electrical infrastructure, including medium voltage applications for larger systems.

- Footprint Constraints: Developing compact or modular designs for facilities with limited space.

- Integration with Existing Systems: Providing control systems that seamlessly communicate with a plant's DCS (Distributed Control System) or SCADA, including advanced features for a thermostat for steam boiler.

- Special Materials: Using corrosion-resistant materials for specific process conditions or water qualities.

- Auxiliary Equipment Integration: Including blowdown tanks, deaerators, feed pumps, and water treatment systems as part of a complete, skid-mounted package.

Customization extends the lifespan of the equipment and significantly improves operational efficiency, making the initial investment more valuable over time. This approach also allows for optimizing energy recovery and overall system performance, whether for a compact industrial unit or a large-scale steam boiler industrial setup.

Application Case Studies

Real-world applications demonstrate the tangible benefits of partnering with experienced electric steam boiler manufacturers.

Case Study 1: Pharmaceutical Facility Upgrade

- Challenge: A pharmaceutical plant required clean, reliable steam for sterilization and process heating, facing strict environmental regulations and high costs associated with their existing gas steam boiler for sale. They needed a solution with zero on-site emissions and precise pressure control.

- Solution: A leading electric steam boiler manufacturer provided a 500 kg/hr, 1.0 MPa electric steam boiler with PLC control and seamless integration into the plant's building management system.

- Results:

- Achieved zero local emissions, meeting stringent cleanroom standards.

- Reduced operating costs by 15% due to high efficiency and lower maintenance.

- Improved process consistency with ±0.01 MPa pressure stability.

- Reduced boiler room footprint by 30%.

Case Study 2: Food Processing Plant Expansion

- Challenge: A food processing company expanded its operations and needed an additional steam source for cooking and sanitization, but had limited space and desired a rapid, flexible solution without the complexities of a water tube steam boiler installation.

- Solution: The manufacturer supplied a skid-mounted electric steam boiler system, complete with feed-water tank, pump, and blowdown separator, rated at 1,200 kg/hr and 0.8 MPa.

- Results:

- Quick installation and commissioning, minimizing downtime.

- Significantly enhanced steam quality, crucial for food product integrity.

- Reduced water treatment chemical consumption due to optimized blowdown control.

- Achieved peak operational flexibility with fast response to demand fluctuations.

Image 4: Boilers undergo rigorous testing before dispatch.

Frequently Asked Questions (FAQ)

A: Standard models typically have a lead time of 8-12 weeks from order confirmation to shipment. Custom-engineered solutions may require 14-20 weeks, depending on complexity and specific component sourcing. Expedited options may be available upon request.

A: Most reputable manufacturers offer a standard warranty of 1-2 years on parts and labor, and often a longer warranty (e.g., 5-10 years) on the pressure vessel, reflecting confidence in their manufacturing quality. Specific terms vary by manufacturer and model.

A: While electric boilers have higher energy conversion efficiency (near 99% vs. 80-85% for gas), the operating cost heavily depends on local electricity and natural gas prices. In regions with favorable electricity tariffs, especially off-peak or renewable energy sources, electric boilers can be more economical. They also save on fuel storage, emissions monitoring, and often have lower maintenance costs.

A: Leading manufacturers provide comprehensive after-sales support, including installation supervision, commissioning services, operator training, preventive maintenance contracts, 24/7 technical assistance, and readily available spare parts. Many offer remote diagnostic capabilities to minimize downtime and ensure continuous operation for any steam boiler industrial application.

Conclusion: Partnering with Leading Electric Steam Boiler Manufacturers

The selection of an electric steam boiler is a strategic decision for any industrial operation aiming for efficiency, sustainability, and reliability. By understanding the meticulous manufacturing processes, advanced technical specifications, diverse application scenarios, and inherent advantages, decision-makers can make informed choices. Partnering with reputable electric steam boiler manufacturers ensures access to cutting-edge technology, tailored solutions, and robust after-sales support, guaranteeing optimal performance and a significant return on investment. The transition towards electrification of process heat is undeniable, making the choice of a high-quality electric steam boiler a future-proof investment in a cleaner, more efficient industrial future.

Image 5: Final quality assurance checks ensure every boiler meets stringent standards.

References

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

- International Organization for Standardization (ISO) 9001:2015 - Quality management systems.

- European Pressure Equipment Directive (PED) 2014/68/EU.

- U.S. Department of Energy (DOE) - Industrial Steam Systems.

- Journal of Energy and Power Engineering - Advancements in Electric Boiler Technology.

-

Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial SolutionsNewsAug.24,2025

-

Reliable Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.23,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025