Electric Steam Boiler Manufacturers: Efficient, Reliable Solutions

Industry Trends in Advanced Steam Boiler Manufacturing

The industrial sector's demand for efficient, environmentally friendly, and highly reliable thermal energy solutions is rapidly evolving. Among these, the market for electric steam boiler manufacturers is experiencing significant growth. This surge is driven by several converging trends: the global push for decarbonization, stricter environmental regulations, and the increasing availability of renewable electricity sources. Businesses are actively seeking alternatives to traditional fossil fuel-fired boilers, such as the conventional gas steam boiler for sale or even wood steam boiler systems, which often carry higher operational emissions and fuel price volatility.

Key trends include the integration of smart control systems, enhanced energy recovery via components like the steam boiler heat exchanger, and a focus on modular designs for easier installation and scalability. The development of advanced materials also contributes to boilers with extended service lives and improved thermal efficiency. Furthermore, the emphasis on robust safety protocols and comprehensive monitoring systems, often incorporating sophisticated thermostat for steam boiler controls, underscores the industry's commitment to operational integrity and personnel safety.

Emerging technologies are also addressing challenges like grid stability and peak demand management, positioning electric boilers as flexible assets in industrial energy ecosystems. The shift towards electric heating is particularly noticeable in regions with abundant and affordable clean electricity, making the investment in high-performance electric boilers a strategic advantage for manufacturers aiming for sustainability and operational excellence.

Manufacturing Process: Precision and Quality by Electric Steam Boiler Manufacturers

The production of high-quality industrial electric steam boilers is a meticulous process demanding stringent quality control at every stage. Leading electric steam boiler manufacturers adhere to international standards such as ISO 9001 and ASME Boiler and Pressure Vessel Code (BPVC) to ensure superior product performance and safety. The typical manufacturing flow involves several critical phases:

1. Design and Engineering

Initial design involves advanced CAD/CAE software to simulate thermal dynamics and structural integrity. Specifications for materials, such as high-grade carbon steel (e.g., SA-516 Grade 70) for pressure parts and stainless steel for heating elements, are precisely defined to ensure corrosion resistance and longevity. This stage also optimizes the boiler's configuration, whether a compact shell-and-tube design or a more complex water tube steam boiler, for specific application requirements.

2. Material Preparation and Fabrication

- Cutting & Shaping: Precision laser cutting or plasma cutting machines prepare steel plates and tubes according to design specifications.

- Forming: Bending and rolling processes form the boiler shell, dished heads, and other cylindrical or conical components.

- Casting & Forging: Specialized components like flanges, valves, and certain fittings may undergo casting (e.g., cast iron for durability) or forging (e.g., high-strength steel for pressure containment) to meet mechanical property requirements.

3. Welding and Assembly

Skilled and certified welders perform manual and automated welding (e.g., TIG, MIG) to assemble the pressure vessel components. Non-destructive testing (NDT) methods like X-ray radiography, ultrasonic testing, and magnetic particle inspection are routinely applied to ensure weld integrity and detect any subsurface defects. This is a critical step for ensuring the safety and operational lifespan of the steam boiler industrial unit.

4. CNC Machining and Component Integration

CNC machining ensures precision for critical parts like flange faces, nozzle openings, and internal mounts for heating elements. After fabrication, heating elements, control panels, safety valves, and the thermostat for steam boiler are integrated. Insulation and external cladding are then applied to maximize thermal efficiency and provide personnel protection.

5. Testing and Quality Assurance

- Hydrostatic Testing: The completed pressure vessel undergoes hydrostatic testing at pressures significantly higher than its operating pressure to verify structural integrity and leak-tightness.

- Functional Testing: Electrical components, control systems, and safety interlocks are rigorously tested under simulated operating conditions.

- Efficiency Testing: Performance parameters such as steam output, purity, and overall efficiency are validated against design specifications.

- Documentation & Certification: Each boiler is accompanied by comprehensive documentation, including material certifications, test reports, and compliance certificates (e.g., CE, PED).

The typical service life for a well-maintained electric steam boiler, manufactured with these rigorous processes and high-quality materials, often exceeds 20-30 years, demonstrating excellent return on investment, particularly for demanding applications.

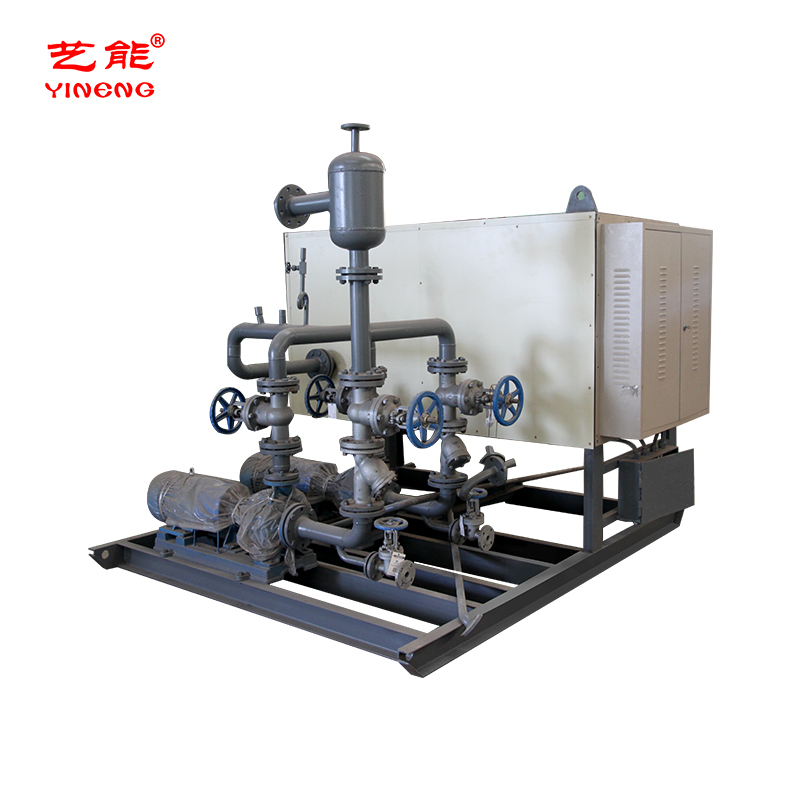

Illustration of a high-efficiency electric steam boiler during assembly.

Technical Specifications of Electric Steam Boilers

Understanding the technical specifications is crucial for selecting the right industrial steam boiler. Modern electric steam boilers offer a range of capabilities to suit diverse industrial needs, from low-pressure heating to high-pressure process steam.

Typical Product Specifications Table: Electric Heating Thermal Oil Boiler (Example)

| Parameter | Specification Range | Unit/Description |

|---|---|---|

| Rated Power | 100 - 8000 | kW |

| Working Pressure | 0.7 - 2.5 | MPa |

| Rated Steam Output | 150 - 12000 | kg/h |

| Design Temperature | 170 - 280 | °C |

| Thermal Efficiency | ≥ 98% | (at full load) |

| Voltage Options | 380V / 400V / 480V / 690V | 3-Phase, 50/60 Hz |

| Control System | PLC with HMI Touchscreen | Remote Monitoring Capable |

| Materials (Pressure Parts) | SA-516 Gr. 70, 304/316L Stainless Steel | High-grade alloys |

These specifications highlight the robust design and high-efficiency performance expected from leading electric steam boiler manufacturers. The near-perfect thermal efficiency is a major draw, minimizing energy waste compared to combustion-based systems.

Application Scenarios Across Diverse Industries

The versatility and clean operation of electric steam boilers make them ideal for a wide array of industrial applications. Their ability to deliver consistent and precise steam or hot thermal oil (as with an electric heating thermal oil boiler) is invaluable.

Target Industries:

- Food & Beverage: Sterilization, cooking, pasteurization, and cleaning-in-place (CIP) processes. The absence of combustion byproducts ensures product purity.

- Pharmaceuticals & Healthcare: Autoclaves, humidification, and sterilization where precise temperature control and ultra-clean steam are paramount. Compliance with GMP standards is easily achieved.

- Chemical & Petrochemical: Process heating, reaction vessel heating, and distillation. The inherent safety of electric heating minimizes explosion risks compared to fuel-fired boilers, even for specialized units like the weil mclain eg 40 steam boiler which might typically use gas.

- Textile & Apparel: Dyeing, finishing, and steaming processes requiring large volumes of steam.

- Pulp & Paper: Pulp cooking, drying, and other process heating applications.

- Water Supply & Drainage: Heating for municipal treatment plants, sludge drying, and district heating systems.

- Manufacturing & General Industry: Humidification, parts cleaning, vulcanization, and various heating demands across a multitude of production lines.

Modular design of an electric steam boiler, suitable for various industrial setups.

Technical Advantages of Modern Electric Steam Boilers

Compared to traditional combustion boilers, modern electric steam boilers offer a compelling suite of technical advantages that translate into significant operational benefits for industrial users.

- Exceptional Energy Efficiency: Electric boilers achieve near 98-99% thermal efficiency, as virtually all electrical energy is converted directly into heat. This contrasts sharply with fossil fuel boilers, where significant heat is lost through flue gases. This inherent efficiency leads to substantial energy saving.

- Zero On-Site Emissions: With no combustion, there are no NOx, SOx, or CO2 emissions at the point of use. This makes them ideal for facilities in urban areas or those with strict air quality regulations, contributing to improved indoor and outdoor air quality.

- Precise Temperature and Pressure Control: Advanced PLC control systems allow for extremely accurate regulation of steam output, temperature, and pressure, which is critical for sensitive industrial processes. The response time is also significantly faster than fuel-fired units.

- Enhanced Safety: Elimination of fuel lines, burners, and combustion hazards significantly reduces the risk of fires and explosions. Automated safety interlocks and robust pressure vessel design minimize operational risks.

- Low Maintenance & Long Service Life: Fewer moving parts, no fuel handling equipment, and reduced thermal stress contribute to lower maintenance requirements and extended operational life. This also reduces downtime and associated costs. Corrosion resistance is often enhanced through superior material selection.

- Reduced Installation Complexity: Without the need for chimneys, fuel storage, or extensive ventilation systems, installation is generally simpler and faster, often requiring less floor space.

- Quiet Operation: Electric boilers operate with minimal noise compared to their combustion counterparts, improving the working environment.

These advantages position electric steam boilers as a superior choice for forward-thinking industrial operations prioritizing sustainability, efficiency, and safety.

Vendor Comparison: Evaluating Electric Steam Boiler Manufacturers

When selecting an electric steam boiler, a thorough comparison of manufacturers is essential. Factors beyond initial purchase price, such as long-term operational costs, reliability, and after-sales support, play a pivotal role. Here's a comparative overview based on typical industry offerings.

Comparison Table: Electric vs. Other Industrial Steam Boiler Types

| Feature/Type | Electric Steam Boiler | Natural Gas Steam Boiler | Heavy Oil/Fuel Oil Boiler |

|---|---|---|---|

| Thermal Efficiency | 98-99% | 80-92% | 75-88% |

| On-site Emissions | Zero (No NOx, SOx, CO2) | Moderate to High (NOx, CO2) | High (NOx, SOx, PM, CO2) |

| Fuel Source Management | Electricity (Grid reliability) | Natural Gas Line | Fuel Storage & Delivery |

| Maintenance Complexity | Low | Medium (burner, flue gas) | High (burner, fuel pre-heating) |

| Installation Requirements | Simple (electrical connection) | Moderate (gas line, chimney) | Complex (fuel tanks, chimney) |

| Operational Noise | Very Low | Moderate | High |

| Footprint | Compact | Moderate | Large (including fuel storage) |

When assessing electric steam boiler manufacturers, look for companies with a proven track record, extensive certifications (e.g., ISO, ASME, CE, UL), and comprehensive global service networks. Reputable vendors often provide detailed energy audits and ROI calculations to demonstrate the long-term benefits of their electric boiler solutions. Partner clients and years of service are strong indicators of reliability and experience.

Customized Solutions and Integration

Recognizing that no two industrial facilities are identical, leading electric steam boiler manufacturers excel in providing highly customized solutions. This bespoke approach ensures optimal integration into existing plant infrastructure and precise alignment with operational demands. Customization can involve various aspects:

- Specific Power Requirements: Adjusting heating element configurations to match available electrical supply and required steam output, including options for high-voltage systems.

- Space Constraints: Designing compact or modular units for facilities with limited floor space or challenging installation environments.

- Process Integration: Tailoring control systems for seamless integration with plant-wide SCADA or DCS systems, optimizing automation and remote monitoring capabilities.

- Material Selection: Utilizing specialized alloys (e.g., Duplex stainless steel) for applications involving corrosive feedwater or aggressive process environments to enhance corrosion resistance.

- Ancillary Equipment: Customizing the integration of essential auxiliaries such as blowdown tanks, deaerators, feedwater pumps, and advanced steam boiler heat exchanger units to maximize system efficiency.

- Compliance & Certifications: Ensuring the boiler system meets specific regional codes (e.g., CE for Europe, UL for North America, or local pressure vessel regulations) for seamless project approval.

Collaborating with experienced engineers from the chosen manufacturer ensures that the boiler system is not just a component, but a perfectly tailored solution that enhances overall plant performance and longevity.

Application Case Studies: Real-World Impact

The practical benefits of electric steam boilers are best illustrated through successful deployments in challenging industrial environments. These case studies highlight their reliability, efficiency, and environmental advantages.

Case Study 1: Pharmaceutical Facility Upgrade

A major pharmaceutical manufacturer replaced an aging natural gas boiler with a 2,500 kW electric steam boiler to support their sterilization and humidification needs. The primary drivers were to achieve zero on-site emissions to comply with stricter local environmental regulations and to reduce operational noise in a sensitive production area.

- Outcome: The facility achieved 99% thermal efficiency, leading to a 15% reduction in overall energy costs due to cheaper off-peak electricity tariffs. Noise levels were reduced by 70%, significantly improving the working environment. The quick response time of the electric boiler also ensured more stable and precise steam delivery for critical processes.

- Experience Highlight: Customer feedback praised the simplicity of operation and the minimal maintenance requirements, leading to increased uptime and reliability.

Case Study 2: Food Processing Plant Expansion

A large-scale food processing plant needed to expand its cooking and CIP capacity. Given the plant's rural location with limited natural gas infrastructure and a desire for sustainable operations, they opted for an electric thermal oil boiler solution (similar to the electric heating thermal oil boiler model). The solution comprised two 1,500 kW units.

- Outcome: The system provided consistent high-temperature thermal oil (up to 250°C), perfectly suited for their frying and heating lines. The modular design allowed for phased installation, minimizing disruption. The total CO2 footprint associated with their heating processes was reduced by leveraging electricity from renewable sources.

- Experience Highlight: The plant manager reported significant savings on fuel transportation and storage costs, alongside enhanced safety due to the absence of combustion. The PLC-based control system allowed for easy integration with existing plant automation.

Advanced control panel for an industrial electric boiler, ensuring precise operation.

Trustworthiness and Support for Industrial Boiler Solutions

Building trust in B2B relationships for critical equipment like industrial boilers requires transparency, robust support, and clear commitments. Reputable electric steam boiler manufacturers prioritize these aspects to ensure customer satisfaction and long-term partnerships.

Frequently Asked Questions (FAQ)

Q1: What are the primary operating costs for an electric steam boiler?

A1: The primary operating cost is electricity consumption. However, this is often offset by high efficiency, lower maintenance, and the elimination of fuel storage/delivery costs. Utilizing off-peak electricity tariffs can further reduce costs.

Q2: How does an electric boiler handle scale buildup?

A2: Like all steam boilers, proper water treatment is essential. Electric boilers are designed for easy descaling, and modern systems include advanced water quality monitoring and automatic blowdown features to minimize scale and corrosion. Regular maintenance checks on the steam boiler heat exchanger are also important.

Q3: What safety features are integrated into electric steam boilers?

A3: Electric boilers typically include multiple layers of safety: automatic pressure relief valves, high/low water level cutoffs, over-temperature protection, redundant heating element controls, and advanced diagnostic systems. All are managed by the integrated PLC and often monitored via a robust thermostat for steam boiler system.

Lead Time and Fulfillment

Typical lead times for standard electric steam boilers range from 8 to 16 weeks, depending on complexity, customization, and current manufacturing load. Expedited options may be available for urgent projects. Fulfillment includes comprehensive packaging, secure shipping logistics, and on-site commissioning support. Detailed project schedules are provided at the order confirmation stage.

Warranty Commitments

Industry-standard warranties for pressure vessels typically cover 2 to 5 years, with electrical components and auxiliary equipment often covered for 12 to 24 months. Specific terms vary by manufacturer and product, always clearly outlined in the sales agreement. Extended warranty options and service contracts are usually available for added peace of mind.

Customer Support and After-Sales Service

Comprehensive customer support is paramount. This includes:

- Technical Assistance: 24/7 remote technical support and troubleshooting.

- Spare Parts: Readily available genuine spare parts and consumables from regional distribution centers.

- On-site Service: Factory-trained technicians for installation supervision, commissioning, preventative maintenance, and emergency repairs.

- Training: Operator and maintenance staff training programs to ensure safe and efficient operation of the boiler system.

Conclusion: The Future of Industrial Steam Generation

The landscape of industrial thermal energy is clearly shifting towards cleaner, more efficient, and smarter solutions. Electric steam boiler manufacturers are at the forefront of this evolution, offering sophisticated systems that not only meet stringent environmental regulations but also deliver significant operational cost savings and enhanced safety. As industries continue to electrify and embrace sustainable practices, the adoption of advanced electric boilers, whether a simple compact unit or a complex water tube steam boiler system, will become an increasingly strategic imperative.

For B2B decision-makers and engineers, investing in these technologies represents a commitment to future-proofing operations, achieving decarbonization goals, and optimizing energy management in an increasingly competitive global market. The long-term benefits in terms of efficiency, reduced emissions, and reliability firmly establish electric boilers as a cornerstone of modern industrial infrastructure.

References

- International Energy Agency (IEA). (2023). Electric Boilers for Industrial Heat: Technology Brief. Retrieved from IEA.org

- ASME Boiler and Pressure Vessel Code (BPVC), Section I: Power Boilers. (2021). American Society of Mechanical Engineers.

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- U.S. Department of Energy, Energy Efficiency & Renewable Energy (EERE). (2022). Steam Best Practices: Boilers and Steam Systems. Retrieved from Energy.gov

-

Electric Steam Boiler Manufacturers: Efficient, Reliable SolutionsNewsAug.25,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial SolutionsNewsAug.24,2025

-

Reliable Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.23,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025