Electric Steam Boiler Manufacturers | Efficient Industrial Solutions

Industry Trends and the Evolution of Electric Steam Generation

The global industrial sector is undergoing a profound transformation, driven by escalating demands for enhanced energy efficiency, reduced carbon footprints, and operational flexibility. Traditional fossil-fuel-fired steam generation, while reliable, faces increasing scrutiny due to environmental regulations and volatile fuel costs. This paradigm shift has propelled electric steam boilers into the spotlight as a viable, sustainable alternative. The market is witnessing a steady transition towards electrification, particularly in regions with abundant renewable electricity sources and stringent emission standards. Consequently, electric steam boiler manufacturers are at the vanguard of innovation, developing advanced systems that promise not only environmental compliance but also superior performance and long-term cost savings for various industrial processes. This segment is poised for significant growth, reflecting the broader industrial commitment to cleaner, more efficient energy solutions.

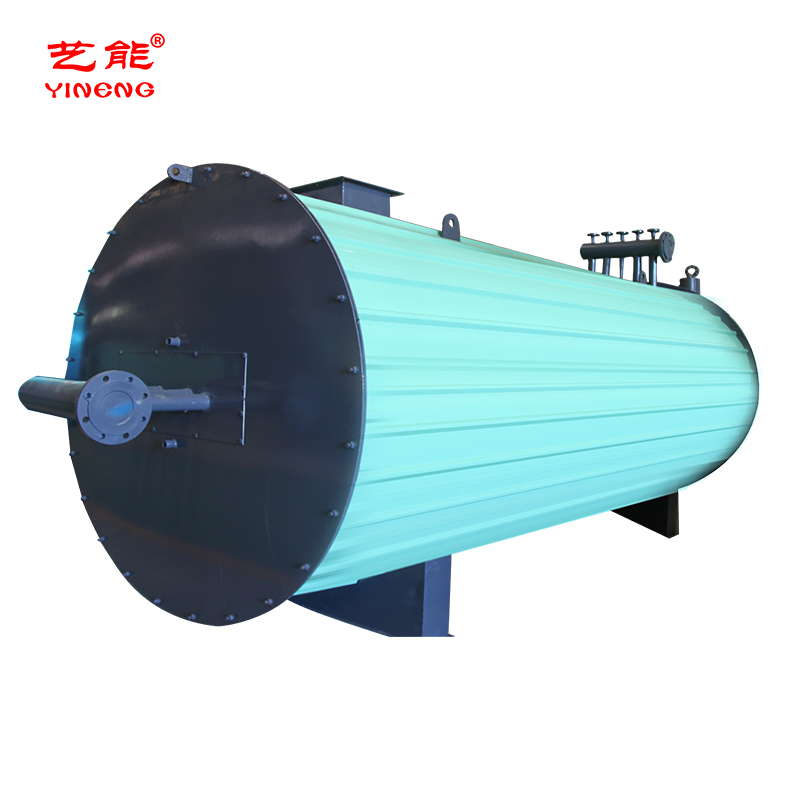

The Advanced Manufacturing Process of Electric Steam Boilers

The production of high-quality electric steam boilers is a complex process demanding precision engineering, stringent material selection, and rigorous quality control. Leading electric steam boiler manufacturers adhere to internationally recognized standards to ensure product reliability and longevity.

Process Flow: From Raw Material to Final Product

- Material Selection & Preparation: High-grade boiler steel, such as SA-210C (medium carbon seamless steel) or ASTM A106 Grade B/C (seamless carbon steel pipe), is meticulously chosen for pressure parts. Heating elements are often made from high-resistance nickel-chromium alloys. All materials undergo strict incoming inspection for chemical composition and mechanical properties, adhering to ASME Boiler and Pressure Vessel Code standards.

- Cutting & Forming: Advanced CNC laser or plasma cutting technologies precisely shape steel plates and pipes according to design specifications. Bending and forming processes ensure accurate component geometries for optimal heat transfer and structural integrity.

- Welding: Critical pressure parts are joined using automated TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding techniques. Welders are certified to ASME Section IX standards, and welds undergo comprehensive Non-Destructive Testing (NDT) including ultrasonic, radiographic, and magnetic particle inspections to detect any flaws.

- Heating Element Integration: Custom-designed electric resistance heating elements, optimized for efficiency and durability, are precisely installed and sealed into the boiler shell or pressure vessel.

- Assembly & Insulation: The boiler shell, heating elements, control panel, and ancillary components (e.g., feed pump, water level controls, pressure relief valves) are assembled. High-density mineral wool or ceramic fiber insulation is applied to minimize heat loss and enhance energy efficiency, especially for a steam boiler industrial application.

- Hydrostatic & Performance Testing: Every boiler undergoes a hydrostatic pressure test at 1.5 times its maximum allowable working pressure, as per industry standards like EN 12952 or ASME Section I, to verify pressure boundary integrity. Electrical systems are tested for safety and functionality. Performance tests validate steam output, pressure accuracy, and efficiency under various load conditions.

- Quality Control & Certification: Throughout the entire process, multiple checkpoints ensure adherence to ISO 9001 quality management systems. Boilers are certified by relevant authorities (e.g., CE, PED, ASME, UL) before shipment.

The emphasis on high-quality materials and advanced manufacturing techniques ensures an extended service life, often exceeding 20 years, for these robust systems. Target industries benefiting from such manufacturing prowess include petrochemical, metallurgy, food & beverage, pharmaceutical, and water supply & drainage sectors. Key advantages demonstrated in typical application scenarios include superior energy saving, exceptional corrosion resistance due to material selection and precise water treatment, rapid startup times, and minimal environmental impact.

Technical Specifications and Performance Parameters

Modern electric steam boilers are engineered for precision, efficiency, and reliability. Understanding their core technical parameters is crucial for optimal integration into industrial processes. These systems typically operate on the principle of resistive heating, where electric current passes through heating elements to generate heat, which is then transferred to water to produce steam.

Key performance indicators include thermal efficiency, which often exceeds 99% due to direct heat transfer with minimal standby losses, a significant improvement over many fossil-fuel alternatives. Pressure ratings vary widely, from low-pressure models (

Control systems are highly sophisticated, often featuring PID (Proportional-Integral-Derivative) controllers, modulating power output to match demand precisely. A reliable thermostat for steam boiler systems ensures accurate temperature and pressure regulation, preventing overpressure and maintaining stable steam supply. Furthermore, many systems are equipped with advanced diagnostics, remote monitoring capabilities, and multi-stage heating element control for enhanced energy management.

Typical Electric Steam Boiler Specifications

| Parameter | Specification Range | Unit/Details |

|---|---|---|

| Power Rating | 12 kW to 1000 kW (and higher for custom) | kW |

| Steam Output | 40 to 1600 kg/h (88 to 3520 PPH) | kg/h or PPH |

| Operating Pressure | 0.5 to 1.6 MPa (72 to 232 psi) | MPa or psi |

| Thermal Efficiency | > 99% | (at full load) |

| Voltage Options | 208V, 240V, 480V, 600V (3-phase) | VAC |

| Steam Quality | Dry Saturated Steam | |

| Control System | PLC with HMI touch screen, PID control | |

| Safety Features | Overpressure, low water, overheat protection | ASME/PED compliant |

Application Scenarios and Strategic Advantages

The versatility of electric steam boilers makes them suitable for a vast array of industrial and commercial applications where clean, reliable steam is paramount. Unlike a gas steam boiler for sale or a wood steam boiler, electric variants offer unique advantages that align with modern operational demands.

Key Application Scenarios:

- Food & Beverage: Sterilization of equipment, cooking processes, pasteurization, and cleaning-in-place (CIP) systems. The absence of combustion byproducts ensures product purity.

- Pharmaceutical & Healthcare: Autoclaves, humidification for cleanrooms, sterilization of instruments and facilities, and process heating for drug manufacturing. High-purity steam is critical.

- Chemical & Petrochemical: Reactor heating, distillation, drying, and process fluid heating where precise temperature control and explosion-proof operation are required.

- Textile Industry: Dyeing, finishing, and steaming processes requiring consistent and clean steam supply.

- HVAC & Humidification: Maintaining humidity levels in large commercial buildings, data centers, and specialized manufacturing environments without the need for flues or chimneys.

Strategic Advantages:

- Environmental Superiority: Zero direct emissions of NOx, SOx, and CO2 at the point of use. This drastically reduces air pollution and simplifies permitting, making them ideal for green initiatives and urban installations.

- High Energy Efficiency: With efficiencies often exceeding 99%, nearly all electrical energy is converted into steam. This minimizes waste and, when coupled with renewable electricity sources, provides a truly carbon-neutral solution.

- Operational Flexibility & Safety: Rapid startup and shutdown times, precise temperature and pressure control, and quiet operation. The absence of combustion eliminates risks associated with fuel storage, exhaust fumes, and open flames, enhancing workplace safety.

- Compact Footprint & Easy Installation: Electric boilers generally have smaller footprints than comparable fossil-fuel units, requiring no fuel lines, flues, or extensive ventilation systems, simplifying installation and saving valuable space.

- Reduced Maintenance: Fewer moving parts, no burners, and no combustion-related fouling mean lower maintenance requirements and extended component life. This also means less need for a complex steam boiler heat exchanger cleaning.

These advantages solidify the position of electric steam boilers as a strategic investment for industries aiming for operational excellence, sustainability, and compliance with future environmental mandates.

Vendor Comparison: Selecting the Right Electric Steam Boiler Manufacturer

Choosing the optimal supplier among electric steam boiler manufacturers is a critical decision that impacts long-term operational efficiency, reliability, and cost of ownership. Beyond initial purchase price, factors such as technological innovation, manufacturing quality, certifications, and after-sales support are paramount. While a weil mclain eg 40 steam boiler might be recognized in the gas-fired segment, the landscape for electric solutions requires distinct evaluation criteria.

Key Comparison Criteria for Electric Steam Boiler Manufacturers:

- Technological Prowess: Does the manufacturer offer advanced control systems (e.g., PLC, HMI), multi-stage heating, and energy recovery options (e.g., blowdown heat recovery)?

- Manufacturing Standards & Certifications: Adherence to ASME, PED, CE, UL, and ISO 9001 demonstrates commitment to quality and safety.

- Customization Capabilities: Ability to tailor boiler design, pressure, voltage, and footprint to specific project requirements.

- After-Sales Support & Service Network: Availability of technical support, spare parts, preventative maintenance programs, and local service technicians.

- Reputation & Industry Experience: Years in the market, client testimonials, and successful installations in similar industries.

- Energy Management Features: Integration with smart grid, demand response programs, or peak-shaving capabilities.

Comparative Analysis of Leading Electric Steam Boiler Offerings (Illustrative)

| Feature | Manufacturer A (Premium) | Manufacturer B (Standard) | Manufacturer C (Budget) |

|---|---|---|---|

| Thermal Efficiency | >99.5% | >98% | ~97% |

| Max. Operating Pressure | 1.8 MPa (260 psi) | 1.2 MPa (174 psi) | 0.8 MPa (116 psi) |

| Control System | Advanced PLC w/ remote IoT | Basic PLC w/ HMI | Electromechanical |

| Certifications | ASME, PED, CE, UL, ISO | CE, ISO | ISO |

| Customization | High (pressure, size, voltage) | Medium (voltage, some features) | Low (standard models) |

| Service Network | Global with local partners | Regional focus | Limited, direct support |

This comparison highlights the diverse offerings available and underscores the importance of aligning a manufacturer's capabilities with specific project needs and long-term strategic goals. Investing in a robust water tube steam boiler from a reputable electric manufacturer ensures not only operational continuity but also compliance and future-proofing against evolving energy mandates.

Customized Solutions for Niche Industrial Demands

Recognizing that no two industrial applications are exactly alike, leading electric steam boiler manufacturers excel in providing highly customized solutions. This bespoke approach ensures that clients receive systems perfectly tailored to their unique operational parameters, spatial constraints, and energy requirements.

Customization can encompass various aspects: from adjusting boiler capacity and operating pressure to integrate seamlessly with existing infrastructure, to modifying electrical specifications (e.g., unique voltage or frequency requirements). Specialized materials for heightened corrosion resistance, modular designs for phased expansion, or skid-mounted units for rapid deployment in remote locations are also common requests. Furthermore, integration with advanced building management systems (BMS) or industrial automation platforms is frequently customized to optimize energy consumption and enhance remote monitoring capabilities. This flexibility is a key differentiator, allowing businesses to maximize efficiency and minimize installation complexities for their specific steam boiler industrial needs.

Application Case Studies: Proven Performance and Reliability

The real-world application of electric steam boilers demonstrates their tangible benefits across various industries. These case studies highlight the expertise and reliability offered by specialized electric steam boiler manufacturers.

Case Study 1: Pharmaceutical Sterilization Facility

A prominent pharmaceutical manufacturer faced challenges with its aging gas-fired boiler, including high NOₓ emissions, escalating fuel costs, and inconsistent steam quality for autoclave sterilization. They engaged a leading electric steam boiler manufacturer to replace the system with a 500 kW, 1.2 MPa electric boiler. The solution provided high-purity, stable steam at 99.8% dryness, critical for aseptic processes. Post-installation, the facility reported a 100% reduction in direct NOₓ emissions, a 15% reduction in overall energy costs due to peak-shaving integration, and significant improvement in steam quality, leading to higher product consistency and reduced maintenance on sterilization equipment.

Case Study 2: Food Processing Plant Upgrade

A large-scale food processing plant required an upgrade to its steam generation system for blanching and CIP processes, prioritizing hygiene and energy efficiency. The existing system struggled with startup delays and fluctuating steam pressure. A custom-designed 800 kW electric steam boiler with multi-stage heating elements was installed. The plant achieved rapid steam generation (full pressure in under 10 minutes), precise temperature control for sensitive products, and virtually eliminated boiler room noise. The facility reported a 20% saving on operational costs annually, primarily from reduced fuel and maintenance expenditures, coupled with enhanced food safety compliance.

Case Study 3: Data Center Humidification System

A new hyperscale data center required a reliable, ultra-clean humidification system to maintain precise environmental conditions. Traditional steam solutions were deemed too complex due to ventilation requirements. A specialized electric steam boiler manufacturers provided a series of compact, modular 50 kW electric boilers. The system delivered consistent, particle-free steam, ensuring optimal humidity levels without compromising air quality. The benefits included a simplified installation, minimal space requirement, silent operation crucial for data center environments, and immediate compliance with stringent environmental certifications.

Ensuring Trustworthiness: FAQ, Lead Time, Warranty, and Support

Trust is paramount in B2B relationships. Reputable electric steam boiler manufacturers prioritize transparency in their operations, product support, and commitments.

Frequently Asked Questions (FAQ):

-

Q1: What are the primary energy savings of an electric steam boiler?

A1: Electric boilers offer near 100% thermal efficiency, converting almost all electrical energy into steam. Savings are realized through reduced fuel costs (especially if using off-peak electricity or renewables), lower maintenance due to fewer moving parts, and elimination of flue losses. -

Q2: Do electric boilers require a specific type of water treatment?

A2: Yes, like all steam boilers, proper water treatment is essential to prevent scaling and corrosion, especially for the heating elements. Most electric steam boiler manufacturers recommend softened or demineralized water to extend element life and maintain efficiency. -

Q3: How do electric boilers handle power fluctuations or outages?

A3: Modern electric boilers are equipped with robust electrical protection systems. In case of a power outage, the boiler safely shuts down. Upon power restoration, many systems offer automatic or semi-automatic restart sequences. -

Q4: Can an existing fossil-fuel boiler be converted to electric?

A4: While technically possible, it is often more cost-effective and efficient to install a new, purpose-built electric steam boiler. Conversion may involve significant modifications to the pressure vessel, controls, and electrical infrastructure, and may not yield optimal efficiency.

Lead Time & Fulfillment:

Standard electric steam boilers typically have a lead time of 8-12 weeks from order confirmation to shipment, depending on specifications and current production schedules. Custom-engineered solutions may require 16-24 weeks due to specialized design and manufacturing processes. Expedited options are sometimes available for urgent requirements.

Warranty Commitments:

Most reputable manufacturers offer a standard warranty of 12-18 months from the date of commissioning or 24 months from the date of shipment (whichever comes first) on boiler pressure parts and major components. Specific heating elements and controls may have separate warranty periods. Extended warranty programs are often available as an optional add-on.

Customer Support & After-Sales Service:

Comprehensive after-sales support is a hallmark of reliable electric steam boiler manufacturers. This includes:

- 24/7 technical assistance and troubleshooting.

- Availability of genuine spare parts and consumables.

- Preventative maintenance contracts and service plans.

- On-site commissioning, operator training, and annual inspections.

- Remote monitoring and diagnostic services for proactive issue resolution.

This commitment to client success ensures long-term operational efficiency and peace of mind.

Conclusion: The Future of Industrial Steam Generation

The trajectory of industrial steam generation is undeniably shifting towards more sustainable and efficient solutions. Electric steam boilers, championed by innovative electric steam boiler manufacturers, represent a critical component of this transition. With their inherent advantages in environmental impact, operational efficiency, safety, and precision control, they offer a compelling alternative to traditional fossil-fuel systems.

As industries worldwide strive to meet ambitious decarbonization targets and enhance operational resilience, the demand for sophisticated electric steam solutions will only grow. By prioritizing robust manufacturing processes, adherence to international standards, comprehensive customer support, and tailored customization, leading manufacturers are not just selling equipment; they are providing future-proof energy solutions that contribute to a cleaner, more efficient industrial landscape.

References

- ASME Boiler and Pressure Vessel Code. American Society of Mechanical Engineers.

- International Organization for Standardization (ISO) 9001:2015 - Quality management systems.

- European Pressure Equipment Directive (PED) 2014/68/EU.

- U.S. Department of Energy, "Steam Best Practices: Electric Boilers."

- "Industrial Steam Systems: A Guide for Facility and Energy Managers." United Nations Industrial Development Organization (UNIDO).

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025