Specifications

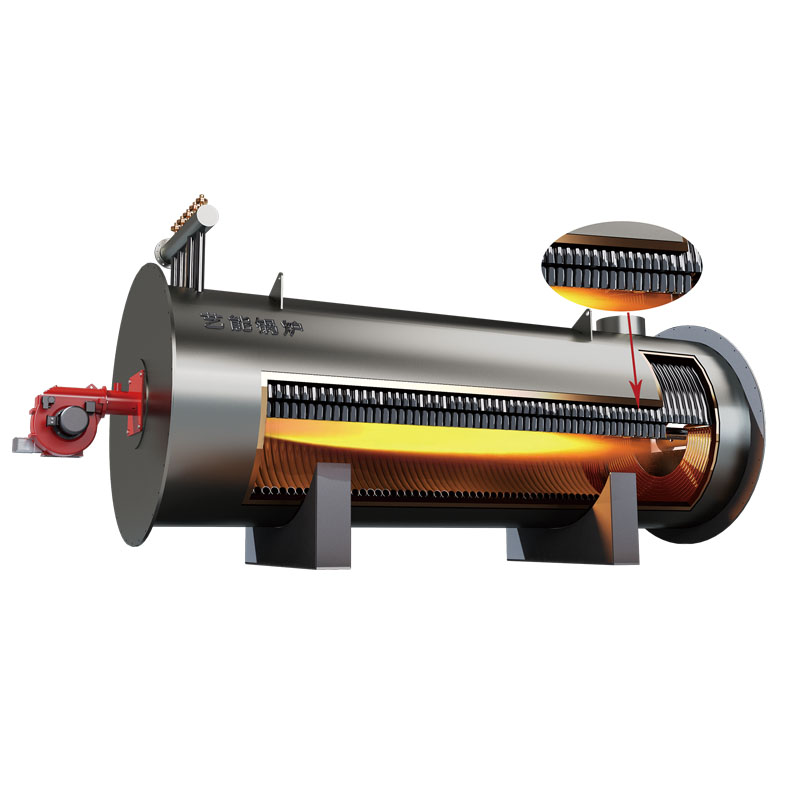

It adopts wet back internal combustion two-return structure. The top of the boiler is equipped with a top coil tube, which effectively prevents the flame from directly radiating the rear wall, increases the radiation heating area, and improves the boiler thermal efficiency.

It adopts wet back internal combustion two-return structure. The top of the boiler is equipped with a top coil tube, which effectively prevents the flame from directly radiating the rear wall, increases the radiation heating area, and improves the boiler thermal efficiency. .Using micro-positive pressure operation, the combustion intensity of the furnace is effectively improved, the volume of the boiler is smaller, and the air leakage of the boiler furnace and the flue is eliminated, and the thermal efficiency is improved.

.Using micro-positive pressure operation, the combustion intensity of the furnace is effectively improved, the volume of the boiler is smaller, and the air leakage of the boiler furnace and the flue is eliminated, and the thermal efficiency is improved. Using high-efficiency condensation technology, effectively reducing the exhaust gas temperature.

Using high-efficiency condensation technology, effectively reducing the exhaust gas temperature. Adopting reasonable structural design and excellent refractory insulation materials, the surface temperature outside the furnace is greatly reduced, heat loss is reduced, and boiler thermal efficiency is improved.

Adopting reasonable structural design and excellent refractory insulation materials, the surface temperature outside the furnace is greatly reduced, heat loss is reduced, and boiler thermal efficiency is improved. Adopt international famous brand burners to adapt to various scenes to ensure quality and safety.

Adopt international famous brand burners to adapt to various scenes to ensure quality and safety.

Features

Its heating surface is made up of closely-arranged coils;

Its heating surface is made up of closely-arranged coils;

The boiler can take diesel, gas, town gas and oil as fuel;

The boiler can take diesel, gas, town gas and oil as fuel; Adopts automatic computer control to achieve DCS control and remote control;

Adopts automatic computer control to achieve DCS control and remote control; The burner and thermal load can be adjustable automatically.

The burner and thermal load can be adjustable automatically. This boiler can be widely used in textile, chemical, wood, oil, rubber, plastics, food, paper, reduction, concentration, dehydration, forest product industry…etc.

This boiler can be widely used in textile, chemical, wood, oil, rubber, plastics, food, paper, reduction, concentration, dehydration, forest product industry…etc.

Technical parameter

|

Capacity |

KW |

240 |

350 |

500 |

700 |

1000 |

1200 |

1400 |

2000 |

2400 |

|

|

X10⁴Kcal/h |

20 |

30 |

40 |

60 |

80 |

100 |

120 |

160 |

200 |

||

|

design pressure Mpa |

1.1 |

||||||||||

|

Max. temperature (℃) |

320 |

||||||||||

|

Circulating oil volume (m³/h) |

18 |

30 |

30 |

60 |

80 |

100 |

100 |

160 |

160 |

||

|

Boiler oil volume (m³) |

0.12 |

0.29 |

0.38 |

0.52 |

0.57 |

0.74 |

0.92 |

1.55 |

1.77 |

||

|

Efficiency (%) |

96.09 |

96.28 |

96.27 |

96.02 |

96.00 |

96.06 |

96.03 |

96.07 |

96.06 |

||

|

Connecting pipe diameter (DN) |

50 |

65 |

65 |

100 |

100 |

150 |

150 |

150 |

150 |

||

|

Boiler weight (kg) |

1632 |

2745 |

3146 |

3771 |

4496 |

4993 |

5680 |

7700 |

8765 |

||

|

Dimension (mm) |

L |

2514 |

2769 |

3250 |

3540 |

3764 |

4374 |

5410 |

5640 |

5560 |

|

|

W |

1320 |

1650 |

1690 |

1710 |

1810 |

1810 |

1810 |

2022 |

2254 |

||

|

H |

1575 |

1993 |

2082 |

1880 |

2291 |

2321 |

2321 |

2480 |

2700 |

||

|

Capacity |

KW |

3000 |

3500 |

4100 |

4700 |

6000 |

7000 |

8200 |

9300 |

12000 |

|

|

X10⁴Kcal/h |

250 |

300 |

350 |

400 |

500 |

600 |

700 |

800 |

1000 |

||

|

Mpa |

1.1 |

||||||||||

|

Max. temperature (℃) |

320 |

||||||||||

|

Circulating oil volume (m³/h) |

180 |

200 |

250 |

250 |

350 |

400 |

450 |

500 |

600 |

||

|

Boiler oil volume (m³) |

1.96 |

3.78 |

4.61 |

5.70 |

7.40 |

8.35 |

9.50 |

10.20 |

13.30 |

||

|

Efficiency (%) |

96.00 |

96.10 |

96.01 |

96.20 |

96.18 |

96.17 |

92.98 |

96.06 |

96.11 |

||

|

Connecting pipe diameter (DN) |

150 |

200 |

200 |

250 |

250 |

250 |

300 |

300 |

300 |

||

|

Boiler weight (kg) |

10267 |

16743 |

17446 |

20669 |

29682 |

32311 |

34640 |

36852 |

49830 |

||

|

Dimension (mm) |

L |

6194 |

6674 |

7456 |

7742 |

8990 |

9441 |

10484 |

10966 |

13500 |

|

|

W |

2254 |

2610 |

2807 |

3240 |

3406 |

3390 |

3560 |

3610 |

3740 |

||

|

H |

2700 |

3150 |

3402 |

3860 |

4117 |

4107 |

4230 |

4280 |

3850 |

||

YQW PRODUCTION PROCESS

-

Skid mounted thermal oil boiler

158

160

Vertical YLL coal fired chain grate thermal oil boiler

158

162

Coal or biomass fired DZL automatic chain grate steam boiler

158

168

WNS energy saving gas or diesel fired steam boiler

158

165

Fixed grate YGL biomass fired thermal oil boiler

158

163

Electric heating WDR automatic steam boiler

158

170

Latest News-

Waste Heat Recovery Boilers: Maximizing Efficiency and SavingsWhen considering a waste heat recovery boiler, understanding the different types of waste heat recovery boiler available on the market is essential for making the right investment.Detail

Waste Heat Recovery Boilers: Maximizing Efficiency and SavingsWhen considering a waste heat recovery boiler, understanding the different types of waste heat recovery boiler available on the market is essential for making the right investment.Detail -

The Future of Thermal Heating SystemsIn today’s industrial world, energy efficiency and reliability are key factors in choosing the right heating systems.Detail

The Future of Thermal Heating SystemsIn today’s industrial world, energy efficiency and reliability are key factors in choosing the right heating systems.Detail -

Industrial Boilers and Heat Recovery Steam GeneratorsWhen it comes to ensuring energy efficiency and reliability in large-scale industries, industrial boilers and heat recovery steam generators (HRSGs) play a vital role.Detail

Industrial Boilers and Heat Recovery Steam GeneratorsWhen it comes to ensuring energy efficiency and reliability in large-scale industries, industrial boilers and heat recovery steam generators (HRSGs) play a vital role.Detail

Afrikaans

Afrikaans

Albanian

Albanian

Arabic

Arabic

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bulgarian

Bulgarian

Cebuano

Cebuano

China

China

China (Taiwan)

China (Taiwan)

Croatian

Croatian

Dutch

Dutch

Esperanto

Esperanto

French

French

Georgian

Georgian

Greek

Greek

Hebrew

Hebrew

Hindi

Hindi

Hungarian

Hungarian

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Javanese

Javanese

Kazakh

Kazakh

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Macedonian

Macedonian

Malay

Malay

Maori

Maori

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Romanian

Romanian

Russian

Russian

Serbian

Serbian

Slovenian

Slovenian

Spanish

Spanish

Tagalog

Tagalog

Tajik

Tajik

Thai

Thai

Turkmen

Turkmen

Ukrainian

Ukrainian

Uzbek

Uzbek

Vietnamese

Vietnamese

English

English