Specifications

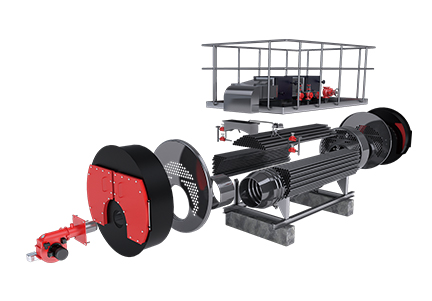

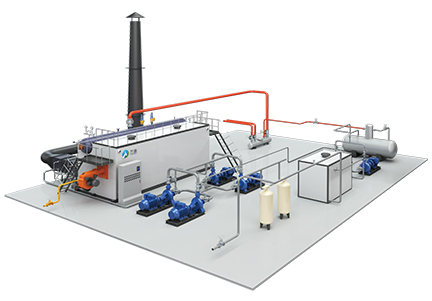

With the horizontal type, wetback and three-backhaul structure design, the boiler has a compact structure, reasonable layout and good-looking appearance.

With the horizontal type, wetback and three-backhaul structure design, the boiler has a compact structure, reasonable layout and good-looking appearance.

With the finned tube economizer arrangement on the tail, boiler has a compact shape for the smaller boiler room.

With the finned tube economizer arrangement on the tail, boiler has a compact shape for the smaller boiler room.

The application of such enhancement components of heat transfer as the corrugated furnace and spirally corrugated tubes not only intensifies the turbulent heat transfer of the high temperature flue gas but also relieves the thermal expansion of the furnace body effectively.

The application of such enhancement components of heat transfer as the corrugated furnace and spirally corrugated tubes not only intensifies the turbulent heat transfer of the high temperature flue gas but also relieves the thermal expansion of the furnace body effectively.

Adopt international famous brand burner, best quality and safety.

Adopt international famous brand burner, best quality and safety.

Adopt best fire-proof and insulation materials, lower the boiler surface temperature, improve the thermal efficiency.

Adopt best fire-proof and insulation materials, lower the boiler surface temperature, improve the thermal efficiency.

Technical parameter

|

Model |

WNS1 |

WNS2 |

WNS3 |

WNS4 |

WNS6 |

WNS8 |

WNS10 |

WNS15 |

WNS20 |

|

|

Capacity |

t/h |

1 |

2 |

3 |

4 |

6 |

8 |

10 |

15 |

20 |

|

Rated pressure |

Mpa |

1.25 (1.6) |

||||||||

|

Rated steam pressure |

℃ |

194(204) |

||||||||

|

Boiler heating surface |

㎡ |

25.5 |

51.3 |

82.3 |

105 |

160.7 |

205.9 |

246.1 |

374.8 |

492.3 |

|

Economizer heating surface |

㎡ |

6 |

10.8 |

17.1 |

20.2 |

26.4 |

41.7 |

40.3 |

49.8 |

66.1 |

|

Efficiency |

% |

92.2 |

93.2 |

92.8 |

92.4 |

92.5 |

92.7 |

92.2 |

92.8 |

92.7 |

|

Boiler weight |

T |

6.3 |

9.5 |

12.2 |

13.5 |

18.9 |

23.5 |

25.6 |

35 |

42.5 |

|

Gas consumption |

Nm³/h |

80.1 |

160.1 |

236 |

314.8 |

407.8 |

553.3 |

691.1 |

1016.6 |

1342 |

|

Diesel consumption |

Kg/h |

68.2 |

136.2 |

200.7 |

271.8 |

347.3 |

476.4 |

599 |

895.3 |

1161 |

|

Dimension (mm) |

L |

3900 |

4300 |

4690 |

5250 |

6100 |

6200 |

6853 |

7520 |

8030 |

|

W |

1900 |

2100 |

2350 |

2550 |

2710 |

2920 |

3210 |

3620 |

3780 |

|

|

H |

2110 |

2400 |

2502 |

2750 |

2980 |

3280 |

3500 |

3820 |

4100 |

|

|

Steam outlet |

DN |

20 |

80 |

80 |

100 |

125 |

150 |

150 |

200 |

200 |

|

Chimney diameter |

mm |

300 |

400 |

450 |

500 |

600 |

700 |

800 |

1000 |

1200 |

Above data based on Gas calorific value 8400kcal/Nm³, diesel calorific value 10250kcal/kg.

PRODUCTION PROCESS

-

Skid mounted thermal oil boiler

165

160

Vertical YLL coal fired chain grate thermal oil boiler

165

162

Coal or biomass fired DZL automatic chain grate steam boiler

165

168

Horizontal YQW gas oil fired thermal oil boiler

165

158

Fixed grate YGL biomass fired thermal oil boiler

165

163

Electric heating WDR automatic steam boiler

165

170

Latest News-

Waste Heat Recovery Boilers: Maximizing Efficiency and SavingsWhen considering a waste heat recovery boiler, understanding the different types of waste heat recovery boiler available on the market is essential for making the right investment.Detail

Waste Heat Recovery Boilers: Maximizing Efficiency and SavingsWhen considering a waste heat recovery boiler, understanding the different types of waste heat recovery boiler available on the market is essential for making the right investment.Detail -

The Future of Thermal Heating SystemsIn today’s industrial world, energy efficiency and reliability are key factors in choosing the right heating systems.Detail

The Future of Thermal Heating SystemsIn today’s industrial world, energy efficiency and reliability are key factors in choosing the right heating systems.Detail -

Industrial Boilers and Heat Recovery Steam GeneratorsWhen it comes to ensuring energy efficiency and reliability in large-scale industries, industrial boilers and heat recovery steam generators (HRSGs) play a vital role.Detail

Industrial Boilers and Heat Recovery Steam GeneratorsWhen it comes to ensuring energy efficiency and reliability in large-scale industries, industrial boilers and heat recovery steam generators (HRSGs) play a vital role.Detail

Afrikaans

Afrikaans

Albanian

Albanian

Arabic

Arabic

Azerbaijani

Azerbaijani

Belarusian

Belarusian

Bengali

Bengali

Bulgarian

Bulgarian

Cebuano

Cebuano

China

China

China (Taiwan)

China (Taiwan)

Croatian

Croatian

Dutch

Dutch

Esperanto

Esperanto

French

French

Georgian

Georgian

Greek

Greek

Hebrew

Hebrew

Hindi

Hindi

Hungarian

Hungarian

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Javanese

Javanese

Kazakh

Kazakh

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Macedonian

Macedonian

Malay

Malay

Maori

Maori

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Romanian

Romanian

Russian

Russian

Serbian

Serbian

Slovenian

Slovenian

Spanish

Spanish

Tagalog

Tagalog

Tajik

Tajik

Thai

Thai

Turkmen

Turkmen

Ukrainian

Ukrainian

Uzbek

Uzbek

Vietnamese

Vietnamese

English

English