Specifications

The drum consists of arched tube sheet and spirally corrugated tube, so as to prevent the tube sheet from cracking.

The drum consists of arched tube sheet and spirally corrugated tube, so as to prevent the tube sheet from cracking.  The ascending calandria are arranged under the drum. With this arrangement, the dead water zone at the bottom of drum is eliminated, and the sludge is difficult to subside on it. As a result, the high-temperature region of drum obtains better cooling, and the bulge phenomenon at the bottom of boiler is eliminated effectively.

The ascending calandria are arranged under the drum. With this arrangement, the dead water zone at the bottom of drum is eliminated, and the sludge is difficult to subside on it. As a result, the high-temperature region of drum obtains better cooling, and the bulge phenomenon at the bottom of boiler is eliminated effectively. The optimal design of the spirally corrugated tube strengthens the heat transfer, speeds up temperature rapidly and enhances the boiler steam rate.

The optimal design of the spirally corrugated tube strengthens the heat transfer, speeds up temperature rapidly and enhances the boiler steam rate.  It is the rational design of arch inside the furnace that improves combustion condition, enhances the dust failing function in it and reduces the pollutant emission of the boiler.

It is the rational design of arch inside the furnace that improves combustion condition, enhances the dust failing function in it and reduces the pollutant emission of the boiler. With good sealing, the wind box is easily to operate and can provide rational wind. Consequently, it reduces the air excess coefficient and increases the boiler thermal efficiency.

With good sealing, the wind box is easily to operate and can provide rational wind. Consequently, it reduces the air excess coefficient and increases the boiler thermal efficiency.

-

-

Technical parameter

Boiler Model

DZL1-0.7-AII

DZL2-1.0-AII

DZL4-1.25

-AII

DZL6-1.25

-AII

DZL10-1.25

-AII

DZL15-1.25

-AII

DZL20-1.25

-AII

Capacity (t / h)

1

2

4

6

10

15

20

Rated Pressure (MPa)

0.7

1.0

1.25

1.25

1.25

1.25

1.25

Rated Steam Temperature (℃)

170

183

194

194

194

194

194

Heating Area (㎡)

30.5

64.2

128

190.4

364.6

594.9

712.1

Effective Area of Grate (㎡)

2

3.6

5.29

7.37

12.67

16.11

22.3

Coal Consumption (kg/h)

191.5

388

780

1155

1890

2250

2980

Smoke Emission Temperature (℃)

158

167.5

165.5

166

156.7

153.5

161.9

Design Efficiency (%)

78.9

78.1

78

79

79.8

80.4

80.1

Weight (t)

15

19.5

25.8

30(TOP)

7.5(BOTTOM)

40(TOP)

32(BOTTOM)

32(TOP)

29(BOTTOM)

32(TOP)

37(BOTTOM)

Dimensions

L × W × H (m)4.6×2.2×2.9

5.3×2.6×3.1

6.5×2.6×3.5

6.3×3.0×3.55

6.6×2.53×1.72

6.5×3.67×3.54

8.2×3.25×2.15

8.4×3.55×3.54

Unpackaged parts

8.6×3.65×3.54

Unpackaged parts

-

DZL PRODUCTION PROCESS

Write your message here and send it to us

-

Skid mounted thermal oil boiler

168

160

Vertical YLL coal fired chain grate thermal oil boiler

168

162

Horizontal YQW gas oil fired thermal oil boiler

168

158

WNS energy saving gas or diesel fired steam boiler

168

165

Fixed grate YGL biomass fired thermal oil boiler

168

163

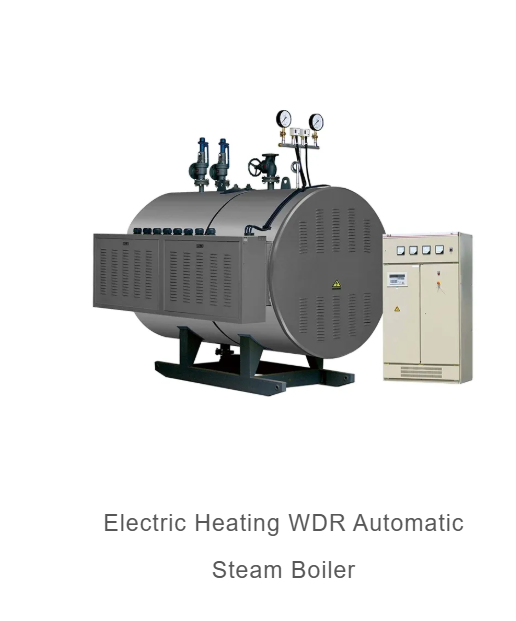

Electric heating WDR automatic steam boiler

168

170

Latest News-

Electric Steam Boiler Manufacturers | Efficient Industrial SolutionsLeading electric steam boiler manufacturers. We offer efficient, reliable industrial steam boilers including gas, water tube, wood-fired, & even parts for Weil McLain EG 40. Explore heat exchangers, thermostats, & solutions for all industrial needs. Get a quote today!Detail

Electric Steam Boiler Manufacturers | Efficient Industrial SolutionsLeading electric steam boiler manufacturers. We offer efficient, reliable industrial steam boilers including gas, water tube, wood-fired, & even parts for Weil McLain EG 40. Explore heat exchangers, thermostats, & solutions for all industrial needs. Get a quote today!Detail -

Wood Steam Boiler for Sale: Maintenance Best PracticesProper maintenance is essential for ensuring the longevity and efficiency of a wood steam boileDetail

Wood Steam Boiler for Sale: Maintenance Best PracticesProper maintenance is essential for ensuring the longevity and efficiency of a wood steam boileDetail -

Gas Thermal Oil Heater Installation Costs AnalysisUnderstanding the complete financial implications of installing a gas thermal oil heater rDetail

Gas Thermal Oil Heater Installation Costs AnalysisUnderstanding the complete financial implications of installing a gas thermal oil heater rDetail